As one of the favorite desserts of consumers around the world, chocolate production technology is constantly improving. From large-scale production in factories to small handmade chocolate workshops, new equipment and processes are driving innovation and development in the industry. In this article, we will focus on three key equipment: liquid chocolate dispenser, manual chocolate depositor, and industrial chocolate mixer, and explore how they empower chocolate production.

Liquid Chocolate Dispenser: The Perfect Combination of Precision and Efficiency

A liquid chocolate dispenser is a kind of equipment designed for chocolate production and processing. Its main function is to distribute molten chocolate liquid into molds or apply it on other food surfaces in a precise manner.

Application Scenarios

Main Advantages

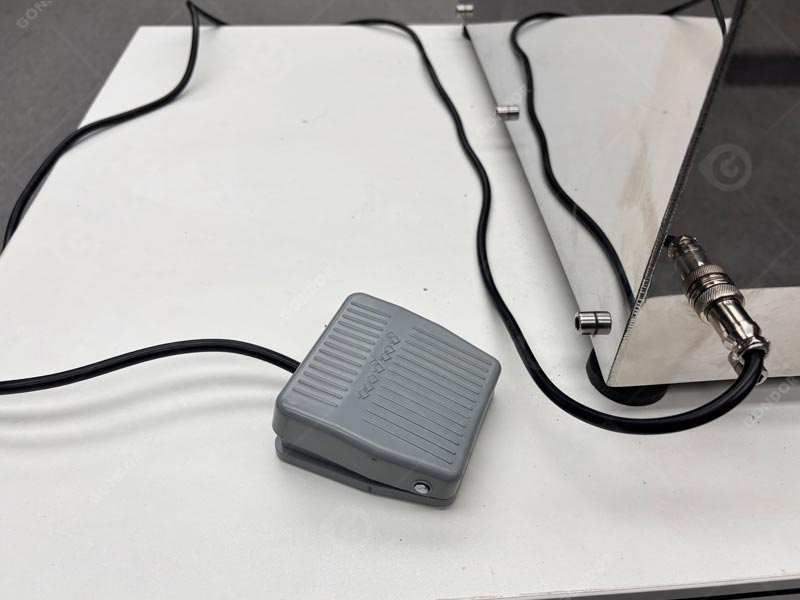

Manual Chocolate Depositor: A Flexible and State-of-the-Art Tool

Compared with automated equipment, manual chocolate depositors offer greater flexibility for craftsmen and small businesses. It allows operators to flexibly adjust the amount of chocolate deposited according to demand, which is very suitable for small batches and diversified production needs.

Features

Usage Scenarios

- Customized Production: Meet personalized needs, such as weddings, holiday chocolate gift boxes, etc.

- Training Purpose: Very suitable for novices to learn how to make high-quality chocolate products.

Industrial Chocolate Mixer: The Basis for High Quality

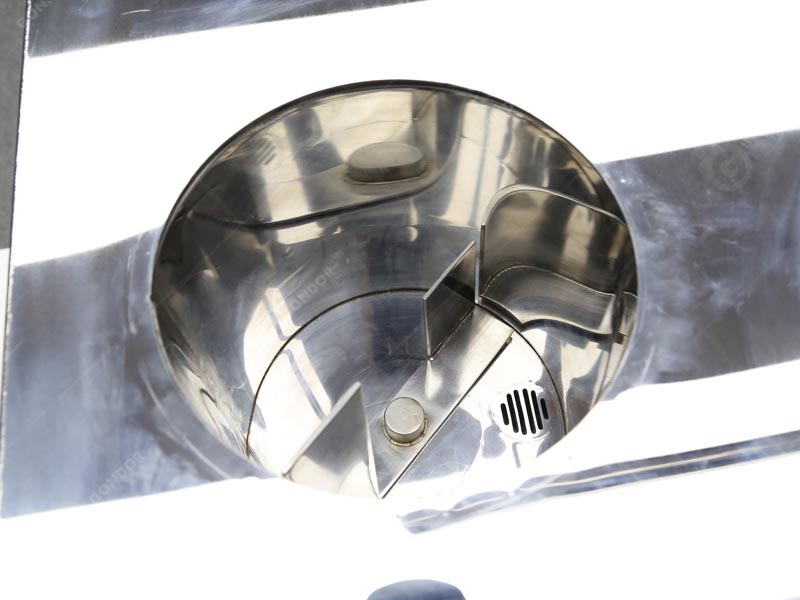

Industrial chocolate mixer is one of the key equipment in chocolate production. It is responsible for mixing raw materials (such as cocoa liquor, sugar, dairy products, etc.) evenly, laying the foundation for subsequent refining and molding.

Core Functions

Technical Highlights

- Equipped with a temperature control system to ensure that the temperature is moderate during the mixing process and does not affect the quality of the chocolate.

- High-speed mixing blade design to shorten mixing time.

Chocolate Mixing Tank

Collaboration: Equipment Integration for Production Optimization

In modern chocolate production, these three types of equipment each have their functions and together form an efficient production chain. For example, after the industrial chocolate mixer mixes the raw materials, it can be directly transferred to the liquid chocolate dispenser to complete the injection molding; and for personalized needs, the manual chocolate injection molding machine provides flexible operation possibilities.

Extension Equipment Recommendation

In addition to the above equipment, other equipment such as chocolate depositing machines, cooling tunnels, and chocolate panning machines also play an indispensable role in chocolate production. By integrating multiple equipment, companies can achieve higher production efficiency and product quality.

Contact us for more chocolate production solutions! We provide customers with one-stop services from equipment selection to installation, helping your chocolate business succeed!