Want to know how to add a uniform, bright and sweet coating to candy? Whether it is chocolate coating, frosting coating or other flavored shells, the candy coater machine provides great convenience for your dessert making. The following are some FAQs to help you quickly understand the functions and applications of this type of equipment.

Gondor Candy Coater Mahcine

Gondor Candy Coating Mahcine

Definition and Function of Candy Coater

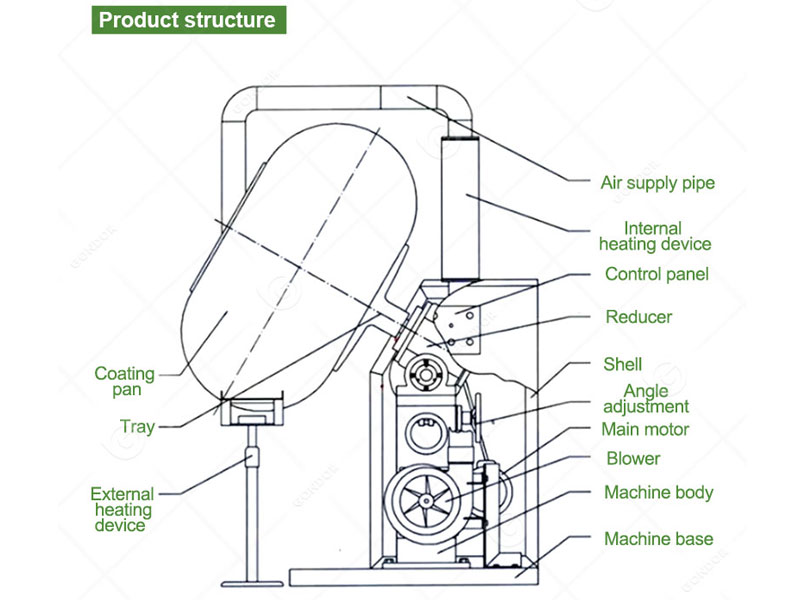

Candy coater machine is a mechanical device used to coat the outer layer of candy. Through multiple technical means such as coating, rolling, heating, etc., it can evenly cover the outer layer of candy with a layer of frosting, chocolate or other flavors.

- Main Function:Form a uniform coating on the outside of the candy to provide a good taste and appearance.

- Application Scenario:Chocolate coating, fruity coating, mint coating, etc.

This equipment is not only used in large-scale candy manufacturers, but also widely used in small and medium-sized dessert shops and home dessert lovers. The coating machine can ensure uniform coating and consistent taste, which is an effect that cannot be achieved by hand.

Working Principle of Candy Coater Machine

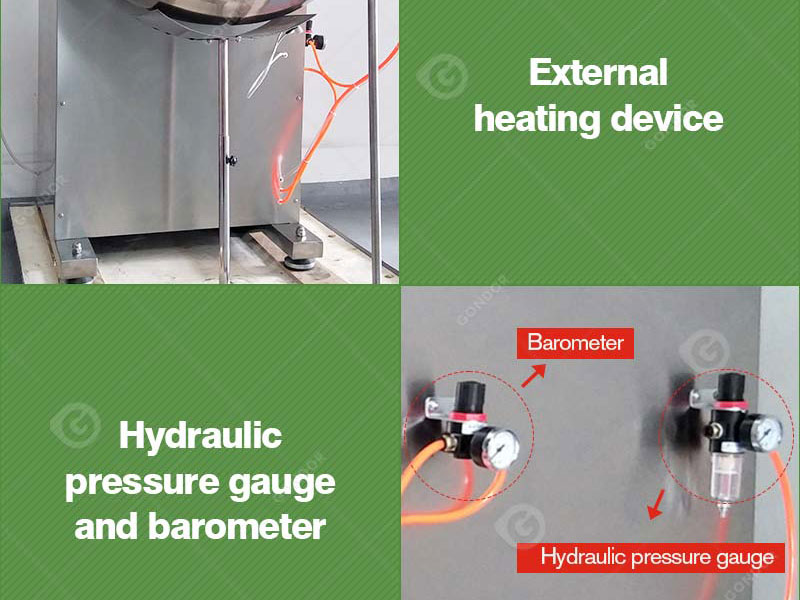

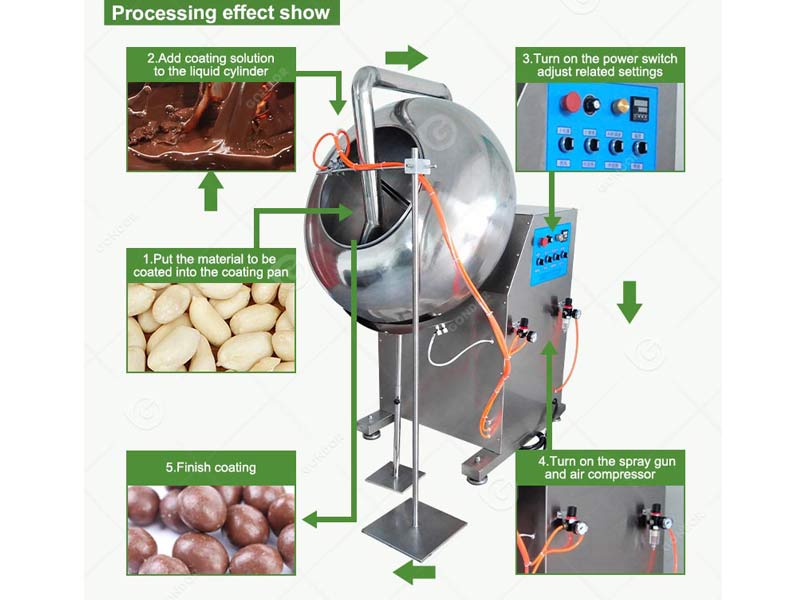

Candy coating machine mainly uses the rolling friction between coating liquid and candy to evenly coat candy. The following is its basic operation process:

Different models vary in drum size, coating speed, temperature control function, etc., but the basic operation process is roughly the same. Some high-end models also have refined temperature control and automation programs, which are suitable for multi-layer coating and complex flavor candy production.

Main Types of Candy Coating Equipment

Candy coating equipment is of various types, from manual equipment to fully automated equipment, to meet the needs of different scales of production. Common types are as follows:

- Small Manual Coating Machine:Suitable for families or small dessert shops, simple operation, but low efficiency.

- Automatic Coating Machine:Suitable for medium-sized manufacturers, with automatic tumbling and temperature control systems, it can quickly complete the coating of large quantities of candies.

- Customized Coating Machine:Dedicated to large factories, it has the characteristics of high efficiency, stability, and low noise, and can support a variety of coating materials and complex processes.

Choosing suitable coating equipment can effectively improve production efficiency and reduce labor costs. In particular, equipment with a high degree of automation can also meet scenarios with higher requirements for candy quality consistency.

Advantages of Using Candy Coating Machines

The advantages of using candy coating machines are significant. Whether it is a professional candy manufacturer or a small-scale dessert maker, you can get the following benefits:

The automatic tumbling and fast coating functions of the coating machine can coat a large number of candies in a short time.

Ensure that the coating of each candy is uniform and the thickness is the same, which brings better taste and visual effects.

Chocolate, fruit syrup, mint coating, etc. can be easily achieved to meet diverse needs.

Through automated equipment, the labor input of manual coating is reduced and production efficiency is improved.

Precautions When Using Candy Coater

There are several key points that need special attention when using candy coater machines:

Daily Maintenance and Care of Candy Coating Machine

Maintenance and care are essential for candy coating equipment, which can extend the life of the machine and ensure the coating effect. Daily maintenance recommendations include:

Gondor Candy Equipment: An Ideal Choice for Improving Candy Production Efficiency

In summary, candy coating machines are an indispensable key equipment in modern candy manufacturing, which can significantly improve efficiency and ensure product quality. As a high-quality brand in the industry, Gondor candy equipment not only covers coating machines, but also provides diversified equipment such as chocolate tempering machine, chocolate sprayer, cooling device, etc., to meet the full process needs from coating to cooling. Choosing Gondor Candy Equipment, you will get professional support and higher production efficiency, so that you can more easily cope with the market demand for high-quality candy products.

Gondor Chocolate Tempering Machine

Gondor Chocolate Tempering Machine