Welcome to our FAQ page about lollipop packaging machine! If you are looking to improve the packaging efficiency of your candy products, we will provide you with comprehensive information about lollipop packaging machines. Our machines are designed to improve production efficiency, ensure high-quality packaging and keep the product fresh. Now, let’s answer your most concerned questions together!

Overview of Lollipop Packing Machine

The lollipop packing machine is an automated equipment designed specifically for lollipop products that can complete the packaging process quickly and efficiently. This machine ensures that each lollipop is hygienically and neatly packaged, extending the shelf life of the product and enhancing its visual appeal. At the same time, the lollipop packaging machine ensures that each package is firm, effectively reducing the risk of contamination and damage during transportation.

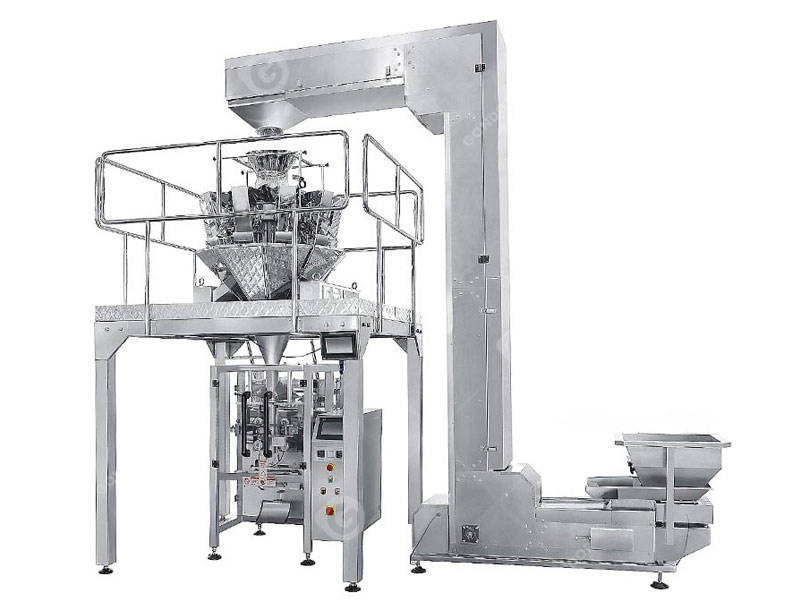

Gondor Lollipop Packing Machine

Working Principle of Lollipop Packaging Machine

The lollipop packaging machine uses advanced technology to package single or multiple lollipops. First, the lollipops are placed on the conveyor belt, and when passing through the packaging area, different packaging methods (such as pillow packaging, twist packaging or flow packaging) are implemented according to needs. The equipment is equipped with precise sensors and high-speed motors, which can complete packaging efficiently and quickly, making it very suitable for mass production.

Main Features of Lollipop Bunch Wrap Machine

Our lollipop bunch wrap machine has many powerful features to ensure a smooth production process:

What Types of Lollipops Are Suitable For

The lollipop wrapper machine can handle lollipops of various shapes and sizes, including:

- Round, oval, flat lollipops

- Lollipop sticks of different lengths

- Lollipops with additional icing or decoration (such as granulated sugar or powdered sugar)

This flexibility allows manufacturers to easily meet the diverse needs of the market.

Advantages of Using a Lollipop Wrapper Machine

The following are important advantages of using a lollipop packaging machine:

Key Factors When Choosing a Lollipop Packaging Machine

When choosing a lollipop packaging machine, you can consider the following factors:

Maintenance Requirements of Lollipop Packing Machines

Regular maintenance of lollipop packaging machines is essential to ensure the normal operation and long life of the equipment:

- Cleaning:Regular cleaning prevents residue accumulation and maintains hygiene standards.

- Lubrication:Lubricate moving parts to prevent wear.

- Parts Inspection:Regularly check wearing parts, such as belts and rollers, and replace them in time.

- Software Update:Some machines are equipped with programmable interfaces, and regular software updates are required to ensure optimal performance.

Explore More Candy Packaging Solutions

To further optimize your production process, you can consider our other series of equipment, such as pillow packing machine, automatic pouch filling machine, etc. Each machine is designed to be seamlessly integrated into the production line, greatly improving the production efficiency of various candy products.

For more information about lollipop packing machines and other related equipment, please feel free to contact us. Our team will help you find the packaging solution that best suits your business!

Vertical Packaging Machine

Pillow Packing Machine