In the candy manufacturing industry, exquisite appearance and unique taste are the key to winning the market, and professional equipment support is indispensable behind them. From colorful soft candies to hard candies of various shapes, the birth of each candy embodies the power of technology and equipment. Today, we will take a deep look at how to make high-quality candies through candy molding machine. Whether you are a large-scale factory or a small entrepreneur, the application of these equipment will help you improve production and quality, and bring customers a more perfect candy experience.

Preliminary Preparation for Candy Making

Before you start, make sure that the equipment and raw materials are in place to achieve the best production results:

Preparation of the Candy Mixture

- Mix the sugar, corn syrup, and water in a double jacket steam kettle.

- Pour the mixture into the candy forming machine and allow the machine to gradually heat the materials to the preset temperature.

- Stir from time to time until the mixture reaches a smooth liquid consistency.

- Tip: Pay attention to the temperature of the machine. Too high a temperature may cause the candy to burn, while too low a temperature may result in the candy not being fully melted.

- When the candy mixture reaches the ideal temperature, carefully add the flavors and colors. This step requires precise timing to ensure that the flavors and colors are evenly distributed.

- Adjust the candy forming machine settings and allow the machine to continue mixing for 2-3 minutes.

- Add the acidulant at the end, which will instantly activate and enhance the fruit flavors of the candy.

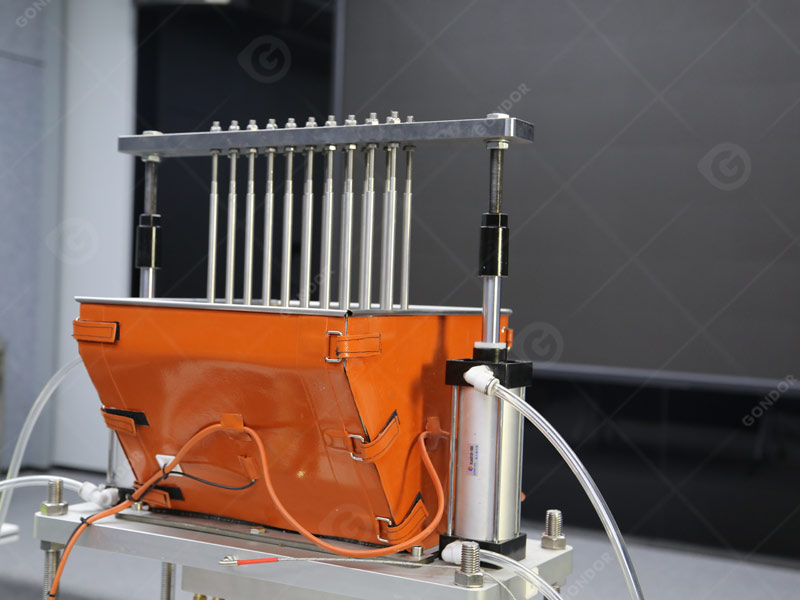

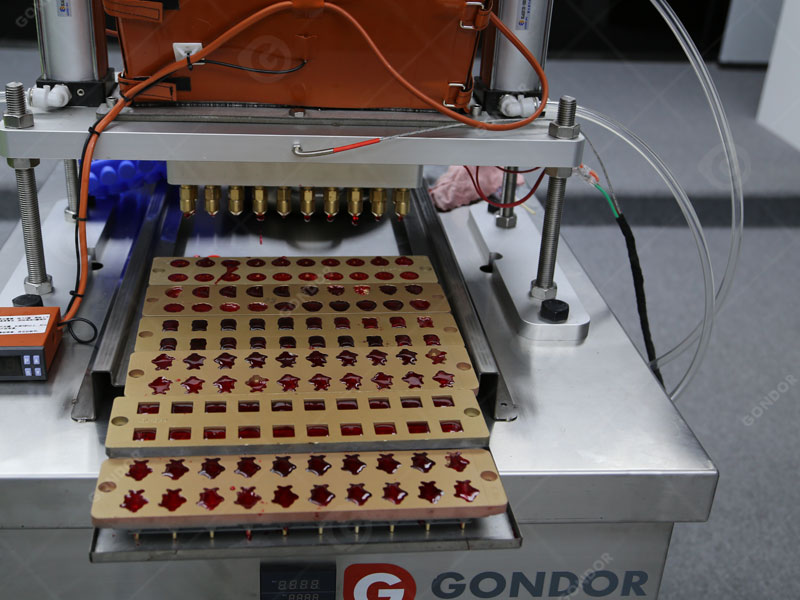

Use a Candy Mold Machine to Mold

Candy mold machines are essential for forming candies, giving them unique shapes, from traditional round shapes to complex custom designs.

- Clean and preheat the molds in the mold machine to ensure that the candies can be smoothly demolded.

- Choose a mold shape that fits your product line, common shapes include hearts, stars, and even custom corporate logos.

- Pour the heated candy mixture directly into the molds of the candy mold machine.

- The machine will evenly distribute the mixture, ensuring that each piece of candy has a consistent thickness and shape.

- Let the candy cool and solidify in the mold. Many candy production equipment is equipped with adjustable cooling functions to optimize the cooling process for different candy types.

- Professional Advice: For mass production, the automatic cooling function of the candy mold machine can reduce waiting time and increase production.

Professional Application of Candy Molding Machines in Production

Candy mold machines play an important role in multiple links of candy production, improving the professionalism of production and the consistency of finished products.

Advantages of Using Candy Forming Machines

- Consistency: The shape, size and texture of each batch of candy are consistent.

- Efficiency: Reduce production time and labor costs.

- Scalability: Easily expand production scale to meet market demand.

- Customization: Create unique shapes and flavors to enhance product differentiation.

Expand Production Lines: Choose the Right Professional Equipment

By equipping with the right equipment, candy manufacturers can achieve increased production, quality and diversification. In addition to candy forming machines, the following equipment can further optimize production lines:

- Candy Cooling Tunnel: An automatic cooling system that provides fast and uniform cooling for freshly formed candies, ensuring that the shape remains unchanged and reducing waiting time.

- Automatic Wrapping Machine: Efficient packaging, supports fast packaging of different candy shapes, adds protection to the product and extends the shelf life.

- Candy Coating Machine: Suitable for producing sandwich, coated or chocolate-coated candies, increasing product types and appeal.