On August 24, Gondor machinery, a renowned and professional food processing machinery company, proudly announced the successful trial run of our latest 3D gummy production line for our customers in Russia. And this innovative 3D gummy production line brings new possibilities to the candy industry, achieving breakthroughs in both production efficiency and product quality, while offering customers more customized and creative candy options. By integrating cutting-edge technology, our company has enhanced both the production efficiency and the consistency, as well as reduced the downtime and maximized output. What’s more, this successful trial run for the Russian customer underscores our dedication to meeting the unique needs of our global clients. In addition, we also help them achieve their production goals with cutting-edge equipment and unrivaled expertise. More details about the customized 3D gummy production line:

Successful Trial Run of 3D Gummy Production Line in Gondor Factory

Customization for 3D Gummy Production Line

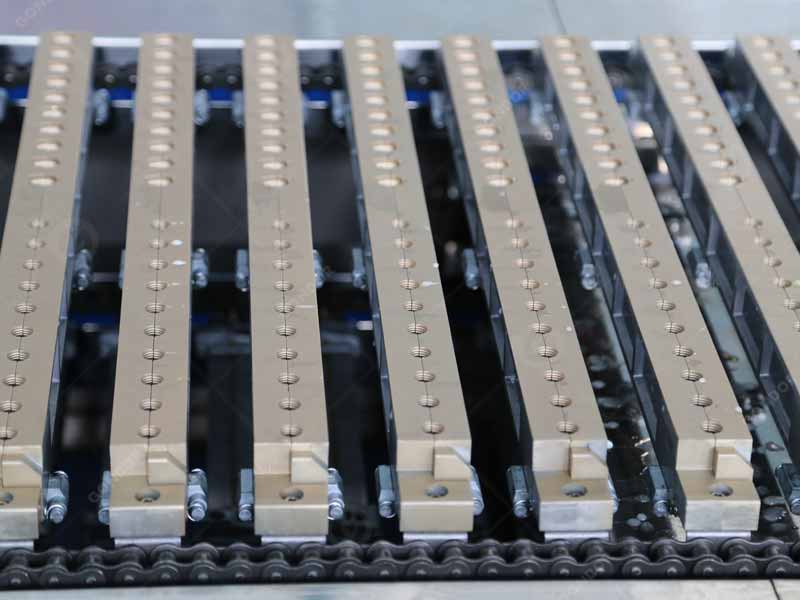

This 3D gummy production line can produce gummy candies 500Kg per hour, and was developed and customized based on the unique needs of our client from Russia. And the customization is particularly focused on three key components: the molds, the hopper, and the pouring heads. Each element was carefully engineered and adjusted to meet the production specifications and quality standards required by the client for the 3D gummy candy making machine. Here are the details about the customized solution for our Russian client:

- The molds used in this 3D gummy production line are highly specialized, which differentiates them from the traditional molds typically found in standard gummy candy making machine. Specifically tailored to produce two distinct shapes, the line can manufacture gummies in the form of classic gummy bears and a unique light bulb shape, which can provide a creative twist to the final product.

- What’s more. the customization of these molds ensures that each gummy candy maintains a consistent and precise shape, enhancing both the visual appeal and quality of the gummies. In addition, the innovative 3D mold design allows for greater depth and realism in each shape, which would not be achievable with regular flat molds used in conventional candy production.

- Our 3D gummy production line is equipped with a uniquely designed hopper system, divided into two independent chambers. This design allows for the simultaneous production of gummies with two different colors and flavors, which not only enhances the production efficiency but also expands the variety of products. The two separate chambers can store and dispense different gummy formulations, and this enables precise proportional control for seamless mixing or independent molding of two types of gummies.

- Therefore, this 3D gummy production line can produce single-colored gummies as well as innovative two-tone or multi-flavor combinations, which cater to the market’s demand for personalized and diverse gummy products. Moreover, this design reduces production line switching costs, as different types of gummies can be produced in the same process, which will significantly minimize the cleaning and reconfiguration time.

- The customization of the pouring system in this 3D gummy production line showcases an advanced setup with dual independent pouring heads. And this depositing system is specially designed for multi-color gummy production, which allows two colors to be poured simultaneously. Moreover, the precise control over these two pouring heads ensures that both the colors and shapes remain consistent during the gummy layering process, which significantly enhances the appearance and overall quality of the final product, making it more attractive to consumers.

- Additionally, the production line includes specially designed pouring needles for making filled gummies. These needles are capable of injecting filling into the gummy base with precise positioning and dosage control. Besides, it guarantees an even distribution of filling in each gummy, which can achieve a perfect center. What’s more, this technology surpasses the traditional gummy making methods and enables the production of more complex, multi-layered, and colorful gummy candies while allowing for flexible changes in fillings, which increases product variety and market competitiveness.

- Overall, this high-precision and multifunctional pouring system enables the production line to meet standard manufacturing requirements while offering clients more personalized and innovative product options.

Comparison Between 2D and 3D Gummy Production Lines

According yo the mold types, there are two types of gummy production lines in the market: traditional 2D gummy making machines and innovative 3D gummy production lines. While both methods share common steps like cooking, molding, and packaging, the 3D gummy production line brings more advanced technology and flexibility. Below is a comparison of the two production lines:

| Aspects | 2D Gummy Making Machine | 3D Gummy Production Line |

| Design Flexibility | Simple, flat designs, often limited to basic shapes like gummy bears, rings, or worms. | Intricate, complex designs, offering full 3D shapes and customizable features. |

| Mold Type | Standard flat molds. | Advanced molds or 3D printing technologies for more detailed designs. |

| Complexity of Shapes | 2D designs with uniform height and shape. | 3D shapes with varying depths, detailed contours, and layers. |

| Production Speed | Faster due to the simplicity of design and process. | Slightly slower due to the complexity of the 3D molds and design. |

| Technology Used | Traditional molding and depositing machines. | More advanced techniques like 3D printing, robotics, and precise depositing. |

| Production Cost | Lower initial setup and running costs due to simpler machinery and molds. | Higher cost due to the need for more sophisticated machinery and custom molds. |

| Product Appeal | Suitable for mass production of conventional gummies. | Unique, customizable products that are more attractive to premium and novelty markets. |

| Customization Options | Limited to shape variations and colors. | Extensive customization, including intricate shapes, layered flavors, or even multi-colored gummies. |

| Batch Size Flexibility | Efficient for larger batches due to less design complexity. | More suitable for smaller, specialized batches due to increased design possibilities. |

| Market Application | Common in large-scale candy production. | Popular for niche markets, luxury products, or special promotions. |

| Texture and Consistency | Consistent due to uniform 2D molds. | Can offer varied textures within a single product, thanks to 3D design. |

| Setup Time for New Designs | Requires new molds, which may take time to produce. | Faster setup with digital design for 3D printing or advanced mold techniques. |

| Material Usage Efficiency | Efficient with minimal material wastage. | Slightly higher material usage due to complexity in designs, but with greater control over precise quantities. |

Key Advantages of the 3D Gummy Production Line

The customized 3D gummy production line demonstrated outstanding performance during the trial run, with the entire process running smoothly. Moreover, the automated production lines operated steadily, and the control system functioned with precision. Besides, during the process, the gummy molding, cooling, and packaging stages were completed efficiently within a short period. In addition, our gummy production line possesses several advantages and these advantages make the 3D gummy production line highly competitive in the modern food industry, which are capable of meeting the demand for high-quality and diversified gummy candies. Check the key advantages below for your reference when planning to buy 3D gummy production lines:

Efficient Automation

The entire gummy production line achieves a high degree of automation, and it can reduce the reliance on manual operation, thus increasing production efficiency and lowering labor costs.

Precise Control

The control system of the 3D gummy making machine is highly accurate, which allows detailed adjustments according to the requirements of different products. So, it ensures consistency in gummy quality and shape.

High-Speed Molding

The gummy molding process is rapid and efficient, and this enables the complex 3D shapes to be formed in a short time, which increases the production speed and capacity in the process of manufacturing gummy candies.

Fast Cooling

Equipped with an advanced cooling system, the 3D gummy production line quickly lowers the temperature of the gummies, which can ensure the shape stability as well as shorten the production cycle.

Strong Flexibility

For the purpose of catering to diverse market demands, our 3D gummy production line is designed with high flexibility. Therefore, this production line can flexibly adapt to different formulas and molds.

Stable Product Quality

Each stage of gummy production, from raw material mixing to final packaging, is strictly controlled by our gummy making machines, which can ensure the consistency of gummy texture, appearance, and quality.

Energy-efficient & Eco-friendly

With an efficient energy management system and eco-friendly materials, our 3D gummy production line can minimize the energy consumption and reduce the waste emissions in the gummy production process.

Integrated Packaging

The automatic packaging machines in our gummy production lines can greatly minimize the manual intervention, improve the packaging efficiency, and ensure the neat, consistent packaging quality.

Easy Operation & Maintenance

The 3D gummy production line features a modular design, which makes equipment maintenance simple and convenient. Meanwhile, it can reduce the maintenance time, and lower the risk of production downtime.

Custommized 3D Gummy Production Line in Gondor Machinery

Importance of 3D Gummy Production Line from Gondor Machinery

The successful trial of the 3D gummy production line by Gondor machinery, a professional food processing machinery company, marks another significant breakthrough in the food processing industry. By leveraging our 3D gummy production line, candy manufacturers will be able to enhance their product competitiveness. At the same, the consumers will enjoy more creative and personalized gummy products.

In the future, our company will continue to advance technological development, and more newly designed production lines from Gondor will set a new standard for gummy production in the future. What’s more, the launch of the 3D gummy production line will showcase a broader range of candy innovation solutions, which will propel the candy manufacturing industry to new heights

Get a Customized Food Processing Solution – Contact Us Today!

The successful trial of the 3D gummy production line for our Russian clients at Gondor Machinery marks a significant milestone in our commitment to providing fully customized solutions. From precision mold adjustments to an advanced hopper design and cutting-edge pouring head, we ensure every production line is perfectly tailored to our customer’s business needs. Looking to elevate your food processing operations? Contact us today and discover how our innovative, reliable food processing and packaging machinery can bring your vision to life. Your success is our mission!