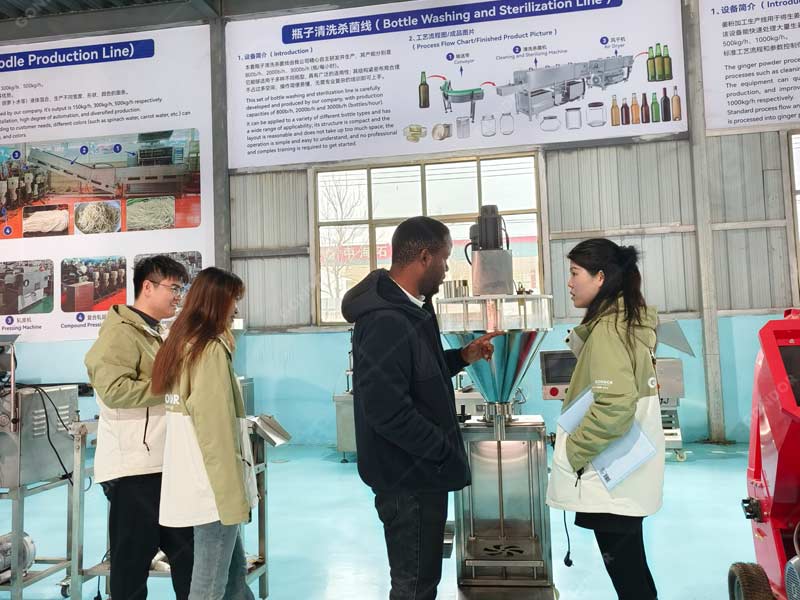

In early January 2025, a Tanzanian customer made a special trip to visit our company to discuss matters related to the industrial peanut butter machine and paste packaging machine, and expressed high satisfaction with the company and factory scale and environment. This visit not only deepened Gondor’s cooperative relationship with the customer but also laid a solid foundation for further cooperation between the two parties in the field of food production equipment in the future.

Customer Needs and Customized Solutions

The customer operates a wide range of products. In addition to solar products, they also plan to invest in a food equipment production line in Tanzania. The customer hopes to build its brand by introducing advanced production equipment and selling equipment to expand its business. During this communication, the customer paid special attention to suppliers who could provide complete production line solutions, and we won the favor of customers with our complete equipment system and professionally customized services.

Main Requirements

- Provide a complete peanut butter production line and paste packaging machine.

- Provide customized production line solutions to ensure that the equipment perfectly matches the factory’s needs.

- Be able to design the production line layout according to needs and provide modification and optimization solutions.

Efficient Communication and Cooperation

In the communication with customers, we understand that customers value a complete nut butter processing equipment solution, so we provide equipment recommendations and optimize the production process. The following is the support we provide to customers:

Customer Visits and Factory Tours

After visiting our factory, the customer spoke highly of our production capacity, equipment, and management, and hoped to have close cooperation in the future. During the inspection, the customer showed great interest in the baby rice cereal and milk production line and had a preliminary discussion on future equipment purchases.

Gondor’s Advantages

To meet customers’ comprehensive needs for production lines, our company not only provides equipment procurement services but also provides a complete set of systematic solutions to ensure efficient operation of production lines, improve production efficiency, and reduce costs. The following are the key support contents we provide to customers:

Expand More Equipment Cooperation Areas

In addition to the industrial peanut butter machine and vertical liquid filling machine, we also provide a variety of food production line equipment. Whether it is equipment procurement, production line design, or after-sales service, we can provide a one-stop solution to help customers expand their business globally.

Through successful cooperation with Tanzanian customers, we believe that we can provide high-quality equipment and services to customers in more regions and jointly embrace greater market opportunities.