As the global demand for chocolate continues to increase, the chocolate manufacturing industry is undergoing technological innovation. From manual production to large-scale industrial production, more and more manufacturers rely on advanced equipment to improve product quality and production efficiency. This article will explore the important role of the industrial chocolate making machine in chocolate factories and look forward to future development trends.

Industrial Chocolate Making Machine: Improving Production Efficiency and Quality

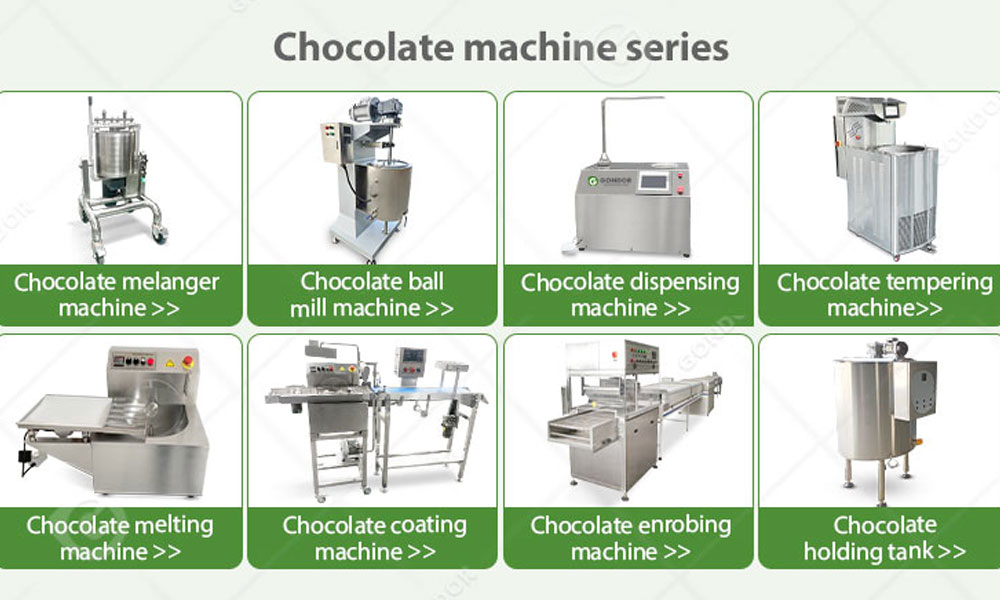

In modern chocolate production, the use of industrial chocolate production equipment is crucial. The following is a brief list of the main equipment and its functions:

These equipment work together to ensure precise control of every link in the production process, which directly affects the quality and taste of the final chocolate.

Efficient Chocolate Factory Machines: Improve the Intelligence of Production Lines

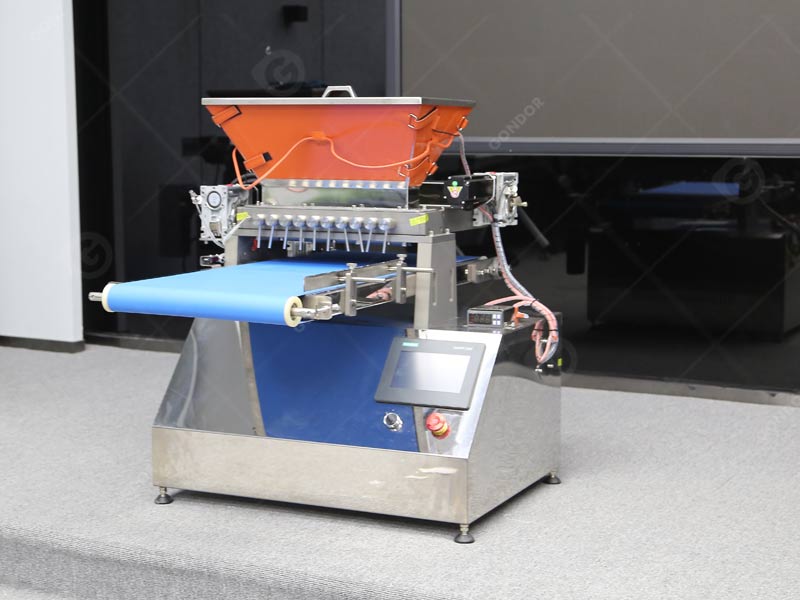

The intelligence of modern chocolate factory machines has improved production efficiency. Here are some key equipment and their functions:

Precisely control the temperature required for chocolate during the production process to ensure the fluidity and taste of chocolate and avoid quality problems caused by unstable temperatures.

Through the automated stirring system, ensure the uniform mixing of chocolate raw materials, avoid uneven manual operation, and ensure the consistent taste of each batch of chocolate.

Achieve efficient packaging of chocolate, reduce manual operation errors, and ensure the neatness and consistency of the packaging appearance, improving the overall efficiency of the production line.

These automated equipment not only reduce human errors but also help chocolate manufacturers ensure high standards in taste, gloss, and texture for each batch of products by accurately controlling temperature, humidity, and mixing ratio.

Cacao Roaster: The First Step in Refined Production

Cocoa roasters play a vital role in chocolate production. Here are their key features:

High-quality cocoa roasters help chocolate manufacturers ensure that they get high-quality cocoa beans from the source, thereby improving the overall taste of the chocolate.

Industry Trends: Green and Intelligent Production

With the improvement of environmental awareness and the increase in consumer health needs, the chocolate industry is moving in a green and environmentally friendly direction. Many chocolate factories have begun to adopt energy-saving and environmentally friendly technologies, such as energy-saving cocoa roasters, to reduce energy consumption and greenhouse gas emissions. At the same time, the introduction of Internet of Things (IoT) technology has enabled intelligent production lines to be realized, which can monitor and optimize production efficiency in real-time. With the expansion of the global market, especially in emerging markets such as Asia and Africa, chocolate manufacturers’ demand for efficient, energy-saving, and environmentally friendly industrial equipment continues to rise, driving innovation and competition in the industry.

More Synergy of Industrial Chocolate Making Machine

In addition to the above equipment, chocolate grinder machines, chocolate molding machines, and chocolate packaging machines are also crucial in the chocolate production process. They work together to ensure smooth production and product quality. With technological advances, future production will be more intelligent, automated, and environmentally friendly. Chocolate manufacturers need to continuously optimize equipment to cope with fierce market competition. By understanding this equipment, companies can improve efficiency, reduce costs, and meet the diverse needs of global consumers.