Gondor machinery, a leading manufacturer of superior milk production lines, proudly announces the successful delivery of our high-quality milk production line to our valued customers in the Philippines. We are deeply committed to ensuring customer satisfaction. So, when a customer from the Philippines reached out to us online in April 2024, our sales and technical teams dedicated themselves to meeting their needs. After four months of communication, our excellence and professionalism earned the trust and positive feedback of our customers. Therefore, we reached an agreement and struck a deal with our customers on this project of milk production line. If you are interested in learning more about this project, please check here to read on, or feel free to contact us!

Milk Production Line Successfully for the Philippines Project

Brief Information about the Philippines Project

Our client from the Philippines is engaged in investment projects and placed an order after securing project contracts for projects closely related to milk products. The client is highly professional and possesses extensive knowledge of the products they are dealing with. Throughout our communication, the client consistently demonstrated a strong command of the product details. Meanwhile, our project manager proactively maintained timely communication with the factory, ensuring that all the client’s inquiries and concerns were promptly addressed. Over time, our project manager’s expertise and our commitment to quality earned the client’s trust, leading to the signing of the agreement.

Milk Production Line in the Philippines

Project Timeline in the Philippines:

- Inquiry Date: April 2024

- Communication Duration: 4 months (from inquiry to order placement)

- Order Placement Date: July 2024

- Production Period: 20 days

- Shipment Date: August 26, 2024

- Product List: Milk Production Line, including the GD-100L Milk Pasteurization Machine, GD-300L Milk Homogenizer, Sanitary Pump, 5HP Glycol Chiller and GD-100L Milk Cooling Tank

Key Machines in Milk Production Line for the Philippines

Regarding the project in the Philippines, our customers purchased a milk production line from us. And this production line includes some essential machines specifically designed to optimize the entire dairy processing workflow. What’s more, these key machines to manufacture milk has ensured the efficient handling, processing, and packaging of milk, which can maintain the high standards of quality and safety. As for the milk production, the production line provides a comprehensive setup, which can not only enhance production capacity but also support sustainable and reliable dairy operations for our customers in the Philippines. For detailed technical parameters of the main machines included in the milk production line for our Philippines customers, please check below:

GD-100L Milk Pasteurization Machine

The milk pasteurization machine or milk pasteurizer is essential for ensuring the safety, quality, and shelf life of milk in a dairy production process. It can be used to heat milk to a specific temperature for a controlled period to kill harmful microorganisms. What’s more, milk pasteurization machines are widely used in dairy production to preserve the milk’s nutritional value and natural flavor while preventing spoilage and contamination.

- Voltage: 220V, 60Hz, Single Phase

- Heating Power: 9 kW

- Stirring Speed: 36 r/min

- Stirrer Power: 0.37 kW

- Machine Dimensions: 100*850*1450 mm

- Tank Dimensions: φ630*400 mm

- Machine Weight: 120 kg

- Capacity: 100 L

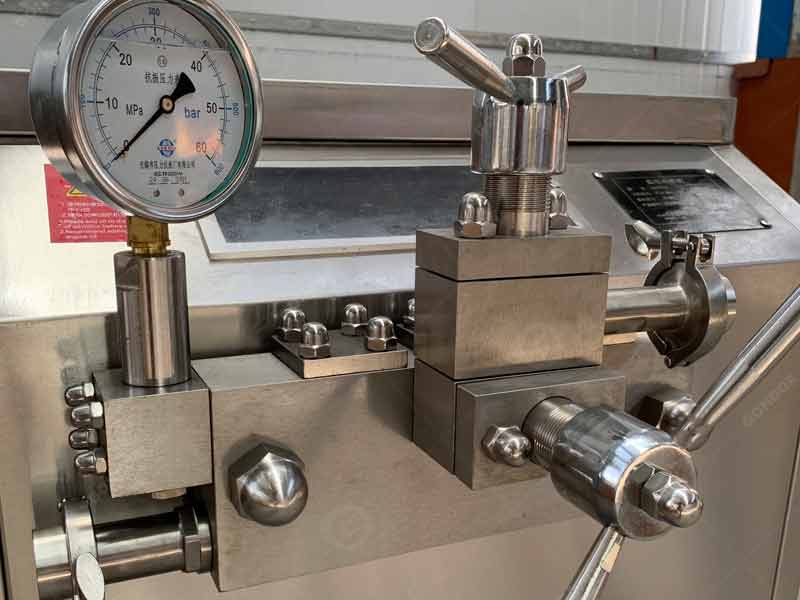

GD-300L Milk Homogenizer or Dairy Homogenizer

As a key component in dairy processing, the milk homogenizer has a function of ensuring even distribution of fat in milk, which results in a smooth texture, prevents cream separation, and enhances product stability. Therefore, many customers choose to buy the homogenizer to produce consistent, high-quality dairy products like milk, cream, and yogurt.

- Capacity: 300 L/H

- Maximum Pressure: 25 MPa

- Motor Power: 3 kW

- Voltage: 220V, 60Hz, Single Phase

- Dimensions: 1010*616*980 mm

Sanitary Pump

When manufacturing the milk product, the sanitary pump can help to maintain the milk quality in environments requiring strict sanitary conditions. It is a hygienic, stainless steel pump used in industries like dairy, food, and pharmaceuticals to safely transfer liquids without contamination. What’s more, it has features of easy cleaning, corrosion resistance, and gentle handling of milk products

- Voltage: 220V, 60Hz, Single Phase

- Flow Rate: 1 T/H

- Inlet/Outlet Diameter: φ38 mm

- Power: 0.37 kW

5HP Glycol Chiller

Our customer from the Philippines also bought an energy-efficient and durable 5HP glycol chiller, which is a powerful cooling system used in industries like brewing, dairy processing, and food production. In the process, it can provide reliable and precise temperature control using glycol, making it ideal for maintaining optimal conditions during fermentation, storage, and other processes.

GD-100L Milk Cooling Tank

The Philippines customer bought a triple-layer insulated tank with a 100-liter capacity, which is designed to maintain milk at the optimal temperature to preserve freshness and quality, and efficiently cool and store milk. Moreover, it is made from high-quality 304 stainless steel, which can ensure durability and hygiene. Additionally, the tank operates on 220V, 60Hz, single-phase power and includes a temperature indicator for precise monitoring.

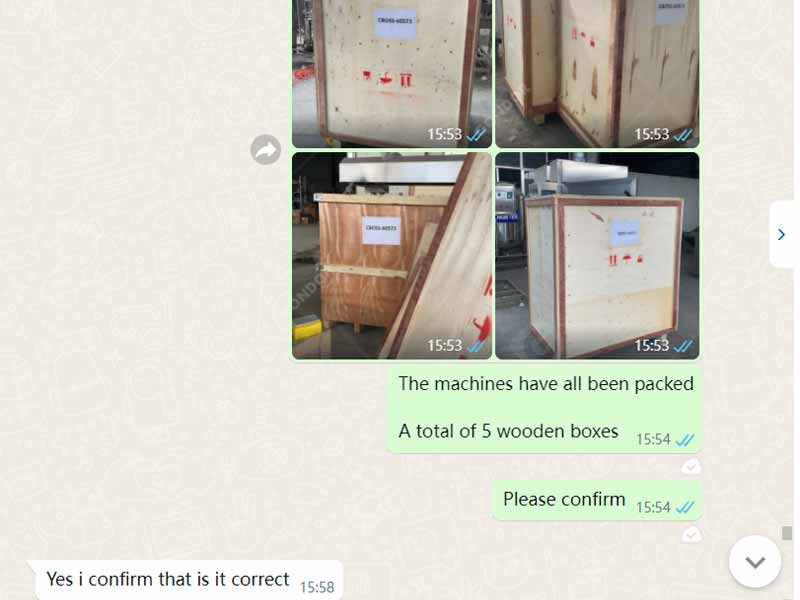

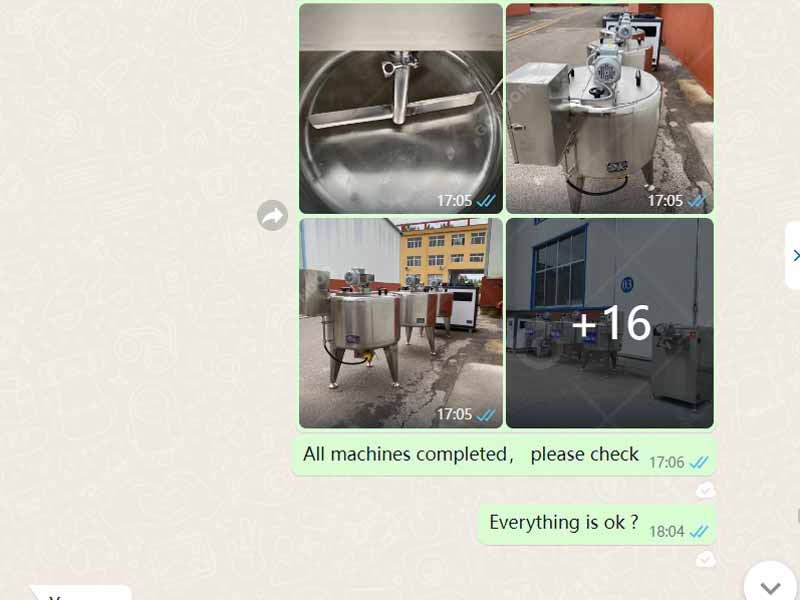

Milk Production Line Shipment to the Philippines

After placing the order, we arranged the production for our customers in the Philippines and then prepared the delivery for our customers after testing all machines before leaving our factory. We also promptly updated the logistics information to reassure our customers from the Philippines.

Positive Feedback of Philippines Project

In the processing of communication, production, and shipment, our team has shown dedication, expertise, and collaboration throughout the project were truly impressive. The project was executed with great attention to detail, and the positive impact exceeded our expectations.

Start Your Food Processing Business with Gondor Machinery

At Gondor Machinery, we are proud to have completed the milk production line project in the Philippines, which has significantly contributed to the growth of the local food industry. With our highly efficient and reliable equipment, backed by professional technical support, this project has been successfully executed and is set to bring lasting economic benefits to the region. When you’re ready to launch a new project in the food processing industry, Gondor Machinery will be your optimal choice, enabling you to access cutting-edge food processing machinery along with a trusted partner.

Whether you are entering an emerging market or expanding an established enterprise, we have the expertise and capabilities to help you achieve your food processing goals. So, whether you are looking to upgrade your existing production line or embark on a new venture in the food processing industry, reach out to Gondor Machinery to gain tailored solutions that will set you on the path to success.