As the global candy market continues to expand, automated packaging equipment has become increasingly essential in improving production efficiency, ensuring product quality, and reducing labor costs. In particular, in the fields of caramel, toffee, and candy packaging, innovative equipment such as the toffee Banane Ka machine and toffee wrapping machine are gaining significant attention from more and more companies. This article will explore how these machines are driving advancements in the candy industry, as well as briefly introduce the relevant technologies that are supporting this growth.

Gondor Toffee Making Equipment

Toffee Banane Ka Machine: The Core Equipment for Producing Perfect Toffee

Toffee Banane Ka machine is the key equipment for making high-quality toffee. This machine ensures the best taste and texture of the candy by precisely controlling the boiling temperature and time of the syrup. Due to the special raw materials and processing methods of toffee, the design of this machine must ensure the sweetness and softness of the candy so that it can be successfully completed in the subsequent packaging process.

The modern toffee Banane Ka machine not only improves the production speed, but also accurately controls the size, shape and hardness of the candies, making every candy on the production line standardized. At the same time, the high performance of this machine greatly reduces the dependence on manual operation, and is an important equipment to meet the needs of large-scale production.

Toffee Wrapping Machine: Improve Packaging Efficiency and Aesthetics

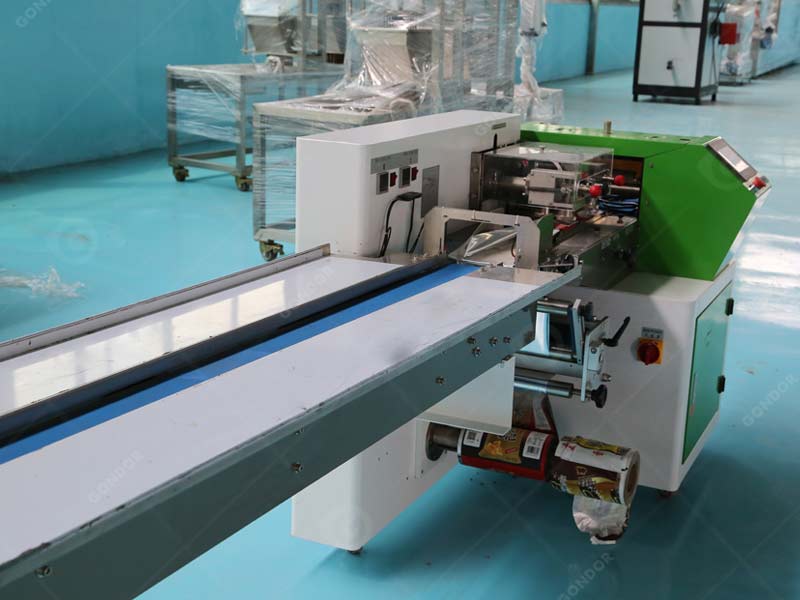

As consumers’ requirements for packaging appearance and quality increase, the toffee wrapping machine has become an indispensable piece of equipment for candy manufacturers. This type of packaging machine can automatically complete a series of processes such as wrapping, folding, and sealing candies, ensuring that the packaging is exquisite and not easily damaged.

By using efficient automation equipment, companies can reduce the cost of manual packaging while avoiding errors and waste caused by manual operations. For companies that require large quantities of packaging, Toffee Wrapping Machine significantly improves production efficiency and meets the market’s demand for rapid supply.

Taffy Wrapping Machine for Sale: Global Market Demand Continues to Grow

With the increasing global demand for candy, taffy wrapping machine for Sale has become a highly sought-after product in the market. Especially in major candy consumption areas such as Europe, America, and Asia, manufacturers have a growing demand for packaging equipment. In order to meet the packaging needs of different candies, Taffy Wrapping Machine adopts a flexible design that can adapt to the packaging needs of candies of different sizes, shapes, and materials.

Taffy Cut and Wrap Machine: Perfect Combination of Precise Cutting and Packaging

In the production of taffy, Gandor 7-Cut block machine and toffee wrapping machine are responsible for cutting and packaging candies respectively. Gandor 7-Cut Block Machine accurately cuts candies into uniform blocks, ensuring that each piece of candy is of the same size, ready for subsequent packaging.

The cut candies are automatically packaged by the toffee wrapping machine, which quickly and accurately completes the wrapping and sealing, ensuring that the packaging is neat and beautiful. The combination of these two devices greatly improves production efficiency, reduces manual errors, and ensures product quality.

Connection and Expansion of Related Machines and Equipment

In addition to the above equipment, a series of other related machines and equipment are also involved in the candy production line, such as batch roller candy, candy depositor, steam jacket kettle, etc. Equipment such as toffee Banane Ka machine and taffy wrapping machine do not work independently. They need to work together with other equipment to complete the complete process from raw material processing to packaging.

Gondor Double Jacketed Steam Kettle

Gondor Equipment Promotes the Development of the Candy Industry

If you are looking for equipment that suits your production line, or if you want to learn more about related products, please feel free to contact our company. We will provide you with tailored equipment and solutions that best meet your needs, helping you stand out in an increasingly competitive market.