Are you considering starting a candy factory and feeling uncertain about choosing the right candy making tools and equipment? For a startup candy factory, it is a critical choice for them to select the right equipment for making candy. Moreover, these tools and equipment for confectionery making should both meet the current production demands and also accommodate the future expansion. Therefore, for investors, it is vital for them to find is it possible to maximize production capacity on a tight budget while ensuring consistent product quality. In this guide, we will explore options of candy making tools and equipment that can be suitable for small-scale and commercial candy manufacturing. All what we do is to help you step-by-step in developing a professional-grade candy manufacturing line. We hope this information provides some valuable insights for you.

Gondor Gummy Candy Making Machine for Sale

Gondor High-capacity Lollipop Candy Making Machine

Different Types of Candy Making Tools and Equipment

In the candy manufacturing process, a range of tools and equipment are involved. In the following sections, we’ll explain each machine’s function, the types of candy it’s suited for, and its role in production. Then, you can you fully understand the complete workflow from mixing to forming and final packaging. Additionally, starting with basic mixers and heating pots and moving to highly efficient automated depositors and packaging equipment, this guide will show you how to optimize production capacity and efficiency through smart equipment investment planning.

Basic Mixing and Heating Equipment

Mixing Machines

- Usage: This equipment ensures thorough blending of ingredients like syrup, flavorings, and spices, and it can achieve uniform taste throughout the candy.

- Recommended Use: Designed for candies where controlled mixing is essential, such as gummies, hard candy, and nougat.

- Key Features: Available in different capacities, mixers are suitable for both small, manual batches and large, automated operations. Automatic candy mixers ensure steady mixing speed and uniformity.

Boiling Kettle

- Usage: Designed to boil syrup to a specific temperature and thickness, and this step plays an important tole in making both hard and soft candies.

- Recommended Use: Ideal for candies requiring high heat processing, such as hard candies and caramel.

- Key Features: Most kettles feature temperature controls for precise heating to prevent syrup crystallization. Most boiling kettles are heated by steam or electricity, and choose the right kettle size tailored to output requirements.

Candy Thermometer

- Usage: Monitors syrup temperature, which is crucial for achieving optimal sugar setting or hardening temperatures.

- Recommended Use: Necessary across candy types, especially hard candies, gummies, and nougat.

- Key Features: Suitable for all production levels. High-quality thermometers offer quick readings, and this ensuring that syrup isn’t overheated or underheated, which will affect the texture and taste.

Candy Molds and Depositor Machine

Candy Molds

- Usage: Used for creating candies in various shapes; once syrup is poured into the mold and cooled, the candy takes its shape.

- Recommended Use: Perfect for creating molded treats like hard candy, gummy candies, and chocolate.

- Key Features: These molds come in a variety of materials like silicone, plastic, or metal. Silicone molds are flexible, ideal for home or small-batch production, while metal molds are durable and fit for large-scale manufacturing.

Candy Depositor Machine

- Usage: It can precisely deposit syrup into molds, saving labor and ensuring uniform candy shapes.

- Recommended Use: Best for medium to large-scale candy production, particularly for high-volume needs.

- Key Features: The vertical and tabletop candy depositor machine is equipped with an automatic dispensing system that ensures precise portions, and it can compatible with molds in various shapes, including stars, hearts, and circles.

Candy Packaging Equipment

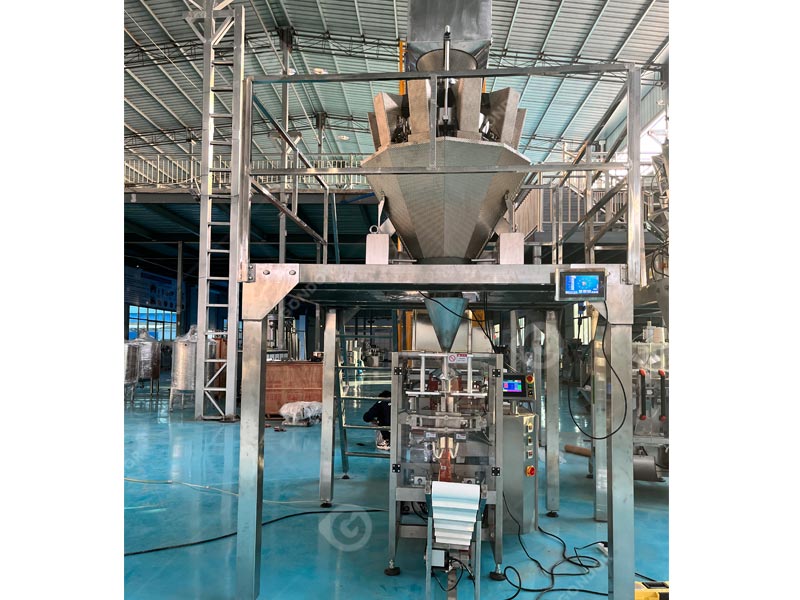

Packaging Machine

- Usage: It can effectively package candy products to keep them sanitary and extend their shelf life.

- Recommended Use: It is ideal for candy factories that require mass packaging, especially for small candy packs and gift boxes.

- Key Features: Candy pillow packing machines are designed for individual candy wraps, whereas vacuum packaging machines are perfect for products requiring long-term preservation. It supports various packaging styles to meet market demands, from individual to mixed packaging.

Sealing Machine

- Usage: Ensures candy bags are securely sealed, and it can preserve product integrity and hygiene.

- Recommended Use: It is suited for medium- and small-scale candy production facilities.

- Key Features: The sealing machines enables quick, sanitary sealing. Heat sealing and automatic sealing machines accommodate different materials, such as plastic or aluminum foil.

Candy Cooling and Forming Equipment

Cooling Tunnel

- Usage: It provides rapid cooling for molded candies, which can secure stable shapes that facilitate packaging.

- Recommended Use: The cooling tunnel is suitable for large-scale candy manufacturing, including hard and soft candies.

- Key Features: It offers quick cooling with a smooth candy surface. Adjustable speeds and temperatures allow for flexibility with different candy types.

Candy Forming Machine

- Usage: Molds syrup into specific shapes, suitable for producing hard candies and other solid confections.

- Recommended Use: Excellent for high-output settings where consistent shape is critical.

- Key Features: It offers quick cooling with a smooth candy surface. Adjustable speeds and temperatures allow for flexibility with different candy types.

Candy Cutting and Press Machine

Candy Cutting Machine

- Function: Efficiently slices syrup into precisely-sized pieces, and this machine is well-suited for sugar cubes and nougat production.

- Ideal Applications: It can be used for candies that need consistent dimensions, such as nougat and soft candies.

- Distinguishing Features: It offers high accuracy with adjustable blade speed and angle to maintain uniformity.

Candy Press Machine

- Function: It is specialized for producing thin, flat candies, such as mint tablets.

- Ideal Applications: Great for tablet-shaped candy production in smaller manufacturing settings.

- Distinguishing Features: High-speed pressing capability with customizable pressure and thickness for large-scale efficiency.

Spraying and Sugar Coating Machine

Candy Spraying Machine

- Usage: This machine is designed to spray chocolate or syrup onto the surface of candies, and it can enhance both texture and appearance.

- Recommended Use: Perfect for creating candies with chocolate shells or a coating layer.

- Key Features: Adjustable spray speed and thickness, which can ensure even coverage depending on the type of coating material used.

Sugar Coating Machine

- Usage: This machine is used for applying sugar powder or coatings on the outer layer of candies, such as sour candies or sugar-coated nuts.

- Recommended Use: Ideal for producing candies with a sugar powder or sugar coating on the surface.

- Key Features: Ensures even coating with various types of sugar layers. The drum-style design is suitable for large-scale production.

Special Tools for Confectionery Making

Candy Spatula

- Usage: Ideal for stirring and scraping syrup to prevent sticking, especially when heating.

- Recommended Use: Perfect for artisanal candy production facilities.

- Key Features: High-temperature resistant, easy-to-clean spatula, designed for repeated use.

Candy Stirrer

- Usage: Helps achieve consistent syrup texture by preventing crystallization as it heats.

- Recommended Use: Best suited for artisanal and low-volume candy-making.

- Key Features: Made from heat-resistant materials, minimizes syrup sticking, and is easy to clean and handle.

Candy Pulling Machine

- Usage: A machine specifically for adding pulled texture and layers to candies such as toffee and decorative sweets.

- Recommended Use: Perfect for candy factories that require a stretched, layered effect in their products.

- Key Features: Equipped with a variable-speed motor, this candy pulling machine ensures even pulling for a uniform finish on every candy piece.

Other Advanced Candy Making Tools and Equipment in Candy Market

In general, the automation and precision of candy production relies on specialized equipment for making candy and enhancing efficiency and product quality across all stages – from ingredient weighing, mixing, and liquid dosing to quality control and maintenance. Moreover, modern systems with advanced technologies can ensure consistency, reduce errors, and streamline production. Below is an overview of essential equipment and their roles.

Efficient Candy Production Solutions by Gondor Machinery

In summary, a candy factory can expand its production capacity and gradually enhance efficiency by choosing the right combination of candy making tools and equipment, from basic production units to automated systems. What’s more, strategic planning in investment and equipment selection is crucial in the startup phase to maintain a balance between capacity and budget.

Gondor machinery is renowned in the confectionery making equipment market for its high-quality machinery and exceptional after-sales service. Moreover, we offer solutions ranging from small-scale machines to fully automated production lines, and our company is the perfect option for candy factories of any size. Ready to embark on your sweet entrepreneurial journey? Visit Gondor machinery to explore our candy manufacturing equipment and connect with our expert team to help you build an efficient and innovative production line!