Jelly candies are loved by consumers around the world for their soft texture, rich flavors and brilliant colors. For companies looking to enter the jelly candy market or increase existing production capacity, jelly candy making machines are crucial equipment. This guide will show you how to use this equipment to produce delicious jelly candies and how to stand out in the competitive market.

Raw Materials and Processes for Making Jelly Candies

Raw Material Selection

The taste and quality of jelly candies directly depend on the raw materials used. The following are the main raw materials for making jelly candies and their functions:

Production Process

The production process of jelly candies requires precise control of temperature, ratio and process flow. The use of jelly candy machines ensures the quality and consistency of each batch of products. The following are common process flows:

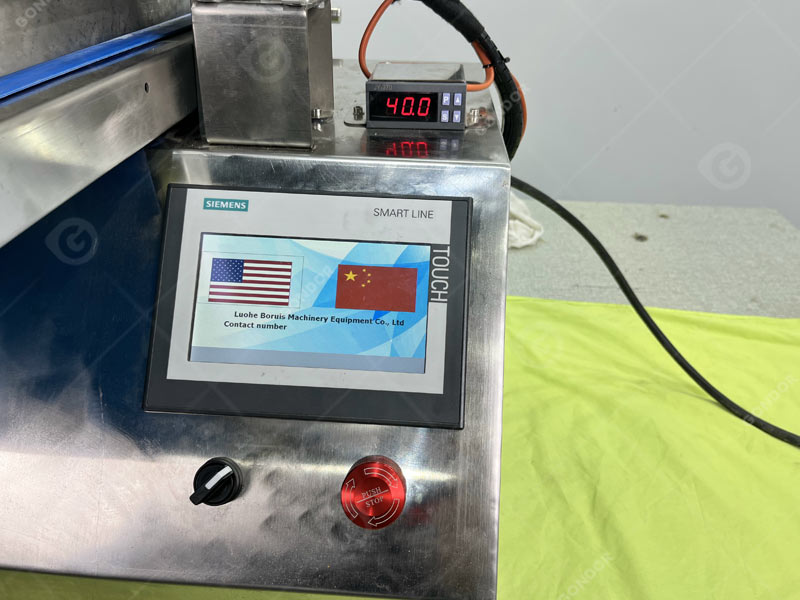

Modern jelly candy machines have intelligent control systems that ensure that the temperature and formula ratio of each process step are accurate and correct, greatly improving production efficiency and product consistency.

Functions and Advantages of Jelly Candy Making Machine

Candy machines have brought great convenience to candy manufacturers. The following are the main functions and advantages of this equipment:

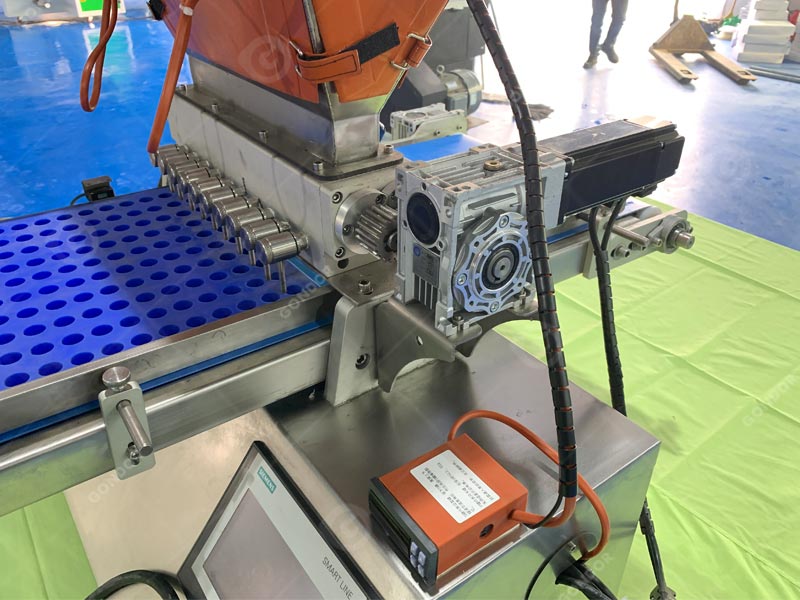

The equipment is usually equipped with an intelligent control system, which can automatically complete the steps of heating, mixing, molding and cooling under preset conditions, greatly reducing the complexity of operation.

By setting parameters, the jelly candy machine can ensure that the formula and taste of each batch of products remain consistent, meeting customers’ needs for product stability.

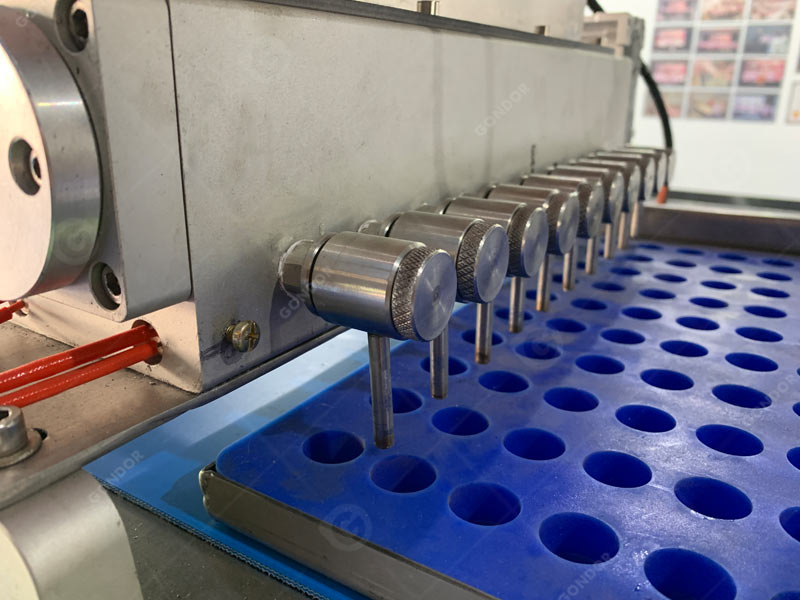

Supporting a variety of molds, you can easily switch to produce jelly candies of different shapes, such as heart-shaped, star-shaped, animal-shaped, etc., to help manufacturers develop creative product lines.

Automated production lines reduce manual operations, reduce production costs, and increase production capacity, bringing manufacturers higher profit margins.

Comprehensive Solutions for Jelly Candy Production Line

For large-scale candy manufacturers, jelly candy production lines are the most ideal choice. Compared with a single jelly candy machine, jelly candy production lines are more comprehensive, including various steps from raw material preparation to finished product packaging. The following are the main components of jelly candy production lines:

Potential and Future Development of the Jelly Candy Market

The market for jelly candies has maintained steady growth worldwide. Consumers are increasingly demanding healthy, natural ingredients and diverse flavors, especially the children’s market and young consumers have a strong demand for jelly candies. With the continuous development of the trend of healthy food, more and more manufacturers choose to use natural juice and sugar-free formulas in their formulas. The jelly candy production line provides technical support for manufacturers, enabling them to flexibly adjust product formulas to meet the diverse needs of consumers.

Contact Gondor to Order More Candy Production Equipment

In addition to jelly candy-making machines, our company also provides other types of candy production equipment, such as chocolate tempering machines, hard candy-making machines, and lollipop candy machines. Welcome to contact us for more machine information and quotes. We will wholeheartedly provide you with high-quality equipment and perfect services to help you achieve greater success in the candy market!

Gondor Chocolate Tempering Machine

Gondor Table Chocolate Tempering Machine

Gondor Lollipop Molding Machine