With the continuous development of the chocolate industry, the production process of chocolate is also continuously innovating. From the processing of chocolate raw materials to the fine blending of finished products, every link is inseparable from the support of efficient and accurate equipment. In this process, chocolate grinder and chocolate grinding technology have become indispensable core technologies, especially in improving chocolate quality and production efficiency.

Chocolate Grinding: A Key Link to Improve Taste and Quality

In the chocolate production process, chocolate grinding is an important step to ensure that the chocolate tastes smooth and delicate. The chocolate grinding process mainly involves refining the cocoa beans through a grinder after preliminary processing to a specific particle size. This process not only helps to reduce the coarse particles in the chocolate, but also promotes the uniformity and stability of the chocolate.

The fineness of chocolate grinding directly affects the texture of the chocolate. The finer the grinding, the smoother the taste. Therefore, choosing an efficient chocolate grinder is crucial for chocolate manufacturers. An excellent grinder can not only improve production efficiency, but also ensure the high quality of the product.

Chocolate Chocolate Melanger: Innovative Technology Drives Productivity

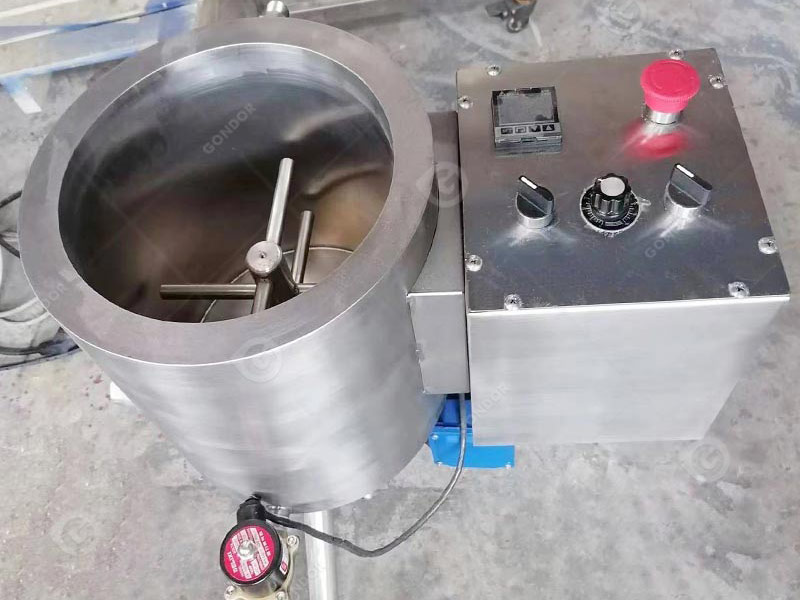

Modern chocolate melangers are designed with full consideration of production efficiency, energy saving and chocolate quality improvement. By adopting innovative technology and sophisticated control systems, modern grinding machines play an important role in optimizing the production process. Here are some key features of modern chocolate grinding machines:

Overcoming Production Bottlenecks and Improving Overall Benefits

With the continuous advancement of chocolate production technology, in addition to chocolate grinding equipment, other links of machinery and equipment are also promoting the efficiency and quality improvement of the entire production process. From the initial processing of raw materials to the final packaging of finished products, each link requires professional equipment to support. The following are several key equipment closely related to chocolate production:

- Chocolate Ball Mill Machine: Use the friction between steel balls and chocolate materials to perform fine grinding to ensure uniform chocolate particle size and improve the smoothness of the taste.

- Chocolate Tempering Machine: Control the heating and cooling process of chocolate, maintain stable temperature, and ensure the ideal fluidity and gloss of chocolate during molding and processing.

- Chocolate Enrobing Machine: Used to provide a uniform coating for chocolate products, widely used in the coating of chocolate candies and nuts, ensuring a uniform and smooth coating.

These devices can not only automate various production links, but also effectively reduce human intervention, optimize the production process, thereby improving production efficiency and ensuring the consistency and high quality of each batch of chocolate.

Towards Fully Automated Chocolate Production

With the rapid growth of the global chocolate market, chocolate manufacturers are facing higher quality requirements and production efficiency challenges. It is crucial to choose advanced high-tech equipment such as chocolate grinders, which can not only improve production efficiency but also ensure the taste and quality of chocolate. In the future, chocolate production will be more intelligent and automated. By adopting comprehensive production equipment solutions, companies can improve production accuracy and meet the market demand for high-quality chocolate. If you want to improve production efficiency and gain more market advantages, Gondor’s chocolate production equipment will be your ideal choice. Contact us to learn more about chocolate-related equipment, we will provide you with tailor-made solutions to help you upgrade your production.