Welcome to visit our official website! We are a professional candy machinery manufacturer dedicated to providing advanced and efficient candy production equipment to customers around the world. This article answers some common questions about candy mold filling machine to help you better understand the functions, usage methods and purchase recommendations of these devices.

Uses and Features of Candy Mold Filling Machine

Candy mold filling machine is a multifunctional candy production equipment designed for filling and molding candies. It is suitable for the production of various candies such as coconut candy and orange candy. This machine can ensure the high consistency of candy in shape, size and weight through precise mold filling and automated system control.

Unique Advantages of Coconut Candy Making Machine

The mixing system equipped with the machine can ensure that the coconut powder and syrup are fully integrated so that each coconut candy maintains a uniform taste.

The temperature requirements in the process of coconut candy making are high. The machine has a built-in temperature control system to prevent the syrup from overheating, sticking or changing the texture.

Candy depositor machine supports the production of coconut candies of different shapes and sizes to meet the diverse needs of the market.

When using this machine to make coconut candy, it is recommended to clean the mold and mixing pipe regularly to avoid coconut residue affecting the operation of the machine and product quality.

Efficient Production Capacity of Orange Candy Making Machine

This gummy depositor machine can not only accurately control flavor and molding, but also provide an efficient and convenient production process, making it an ideal choice for the production of a variety of candies such as coconut candy and orange candy.

Ease of Installation and Operation of the Machine

- Place the machine on a stable and flat ground, and ensure that the surrounding environment is clean and ventilated for the safety of operators and equipment.

- Connect the power supply and ensure that the voltage matches the machine’s requirements. Check whether the grounding of the machine is stable to prevent malfunctions caused by power fluctuations.

- Check the installation of each component, especially the mold and filling system, to ensure that there is no looseness or abnormality. Ensure that all pipes and stirring devices are firmly connected.

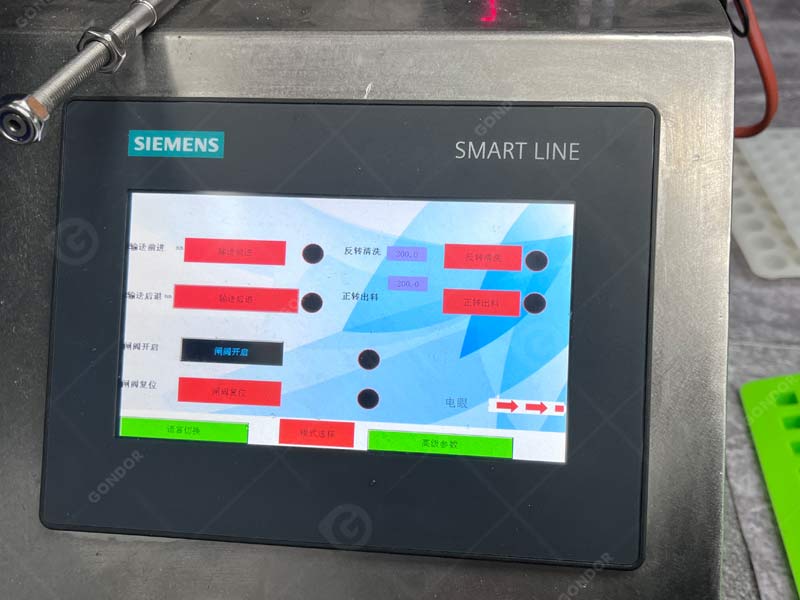

- The machine is equipped with a digital touchscreen operation interface, and users can enter the parameters required for production on the display, such as syrup temperature, filling amount, stirring speed, etc.

- The menu design is simple and intuitive, and operators can quickly get started without complex technical backgrounds. The interface supports multi-language options, which is convenient for global customers to operate.

- Preheating: Before formal production, start the machine for preheating to make the syrup temperature reach the set value. The preheating time can be monitored in real-time on the interface.

- Filling and Stirring: Pour syrup or raw materials into the machine’s feed port and start the stirring and filling process. The machine will automatically control the amount and rate of each filling to ensure consistent molding quality for each candy.

- Mold Selection and Replacement: Users can choose different molds according to their needs, and adjust the machine to automatically adapt to the production of candies of different shapes. Mold replacement is simple and quick, and the operator only needs a small amount of time to complete it.

- After use, it is recommended that the operator disassemble the mold and filling pipe according to the cleaning process, and clean them with warm water or special detergent to avoid residual syrup affecting the quality of the next batch of products.

- Key components of the machine, such as the stirring system, heating device and touch screen, should be regularly inspected and cleaned to help extend the service life of the equipment.

After-Sales Service Support Content

We provide comprehensive after-sales service, including installation, training, and maintenance of the machine. In addition, if you encounter problems during use, our technical support team is always online to answer your questions.

- Technical Consultation: Free telephone and online consultation services.

- Accessories Supply: Long-term supply of original accessories for the machine to ensure that customers can replace worn parts at any time.

- On-Site Service: According to customer needs, we can provide paid on-site service to help solve complex problems that arise with the machine.

Other Related Candy Production Equipment Recommendations

In addition to the candy mold filling machine, we also provide the following related equipment:

- Chocolate Coating Machine: Suitable for producing candies or other snacks wrapped in chocolate.

- Gummy Candy Making Machine: Designed specifically for gummy candy production, supporting a variety of fruit flavors and colors.

- Lollipop Making Machine: Automatic molding, cooling, and packaging integrated lollipop production equipment.

Through this FAQ, I hope you have a deeper understanding of Candy Mold Filling Machine, Coconut Candy Making Machine, and Orange Candy Making Machine. If you have more questions, please feel free to contact us. We look forward to working with you to achieve a better candy business together!