In recent years, as consumers’ demand for high-quality chocolate continues to grow, chocolate manufacturers are accelerating the upgrading of equipment to ensure the flavor, taste and production efficiency of their products. In particular, driven by advanced equipment such as the bean to bar chocolate making equipment, chocolate boiler machine, and chocolate sweet machine, the chocolate industry has ushered in new development opportunities.

Bean to Bar Process: A Revolution in Chocolate Making

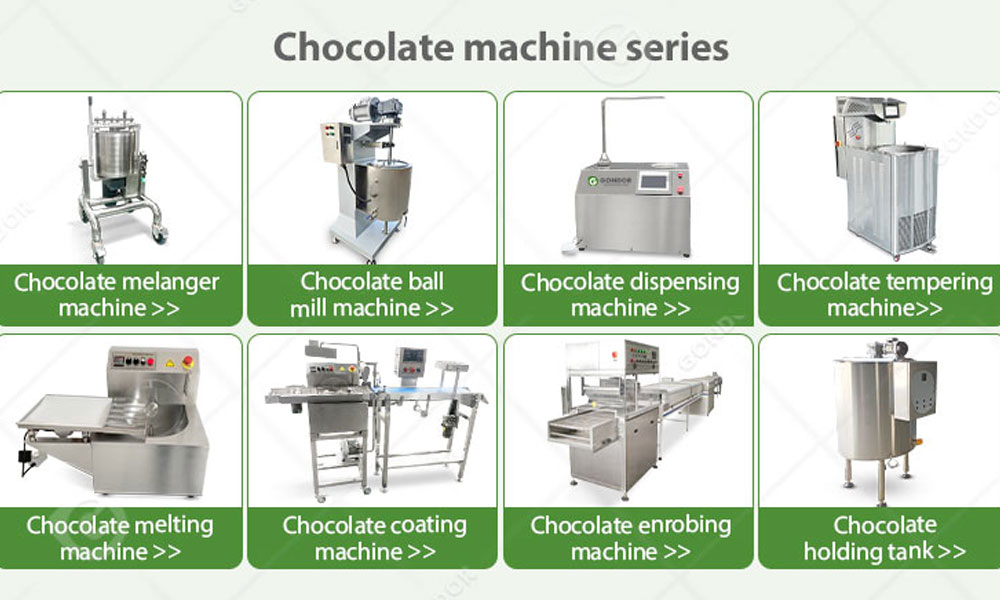

“Bean to bar” is a production method that controls the entire process from cocoa beans to chocolate. Compared with traditional industrial production, it can better retain the natural flavor of cocoa beans and meet personalized and handmade needs. In this process, bean to bar chocolate making equipment is crucial, including:

With the growing demand for fine chocolate, more small and medium-sized manufacturers invest in bean-to-bar chocolate equipment to improve quality and create unique brands.

Chocolate Boiler Machine: Ensure Accurate and Stable Chocolate Boiling

Boiling chocolate is a key link that affects the taste and gloss. The chocolate boiler machine is dedicated to heating and melting chocolate, accurately controlling the temperature to prevent agglomeration or scorching.

Main Features of Chocolate Boiler Machine

In modern chocolate factories, chocolate boiler machines are usually used in conjunction with other equipment (such as conching machines and pouring machines) to form a completely automated production line to improve production efficiency and product quality.

Chocolate Sweet Machine: Improving Chocolate Candy Production Efficiency

For companies producing chocolate sweets, chocolate sweet machines are essential. This type of equipment can achieve multiple functions such as chocolate enrobing, coating, filling, cooling, etc., and is suitable for producing a variety of products such as chocolate-filled candies, truffles, chocolate-coated nuts, etc.

Application of Chocolate Sweet Machine

- Enrobing Machine: Coat nuts, biscuits, or candies with a uniform layer of chocolate.

- Filling Chocolate Machine: Suitable for producing chocolate-filled chocolates, such as caramel filling, hazelnut paste filling, etc.

- Chocolate Cooling Tunnel: Ensure that chocolate is cooled at the right temperature to form a smooth and uniform appearance.

In the context of increasingly fierce market competition, manufacturers can improve production efficiency and reduce labor costs while ensuring product consistency and quality by introducing efficient chocolate sweet machines.

Future Trends in Intelligence and Customization

With the advancement of technology, chocolate production equipment in the future will be more intelligent and automated. For example, AI-driven intelligent temperature control systems can automatically adjust the temperature according to the characteristics of cocoa beans to ensure the best cooking effect; 3D printing technology is expected to bring a new experience of personalized chocolate.

In addition, as consumers pay more attention to healthy food, low-sugar, sugar-free, and high-cocoa chocolate products are on the rise. Future chocolate equipment will pay more attention to the development of healthy formulas to meet market demand.

More Equipment Recommendations

If you are looking for efficient and professional chocolate processing equipment, please contact us. We will provide you with the best solutions to help your chocolate business reach new heights!