With the rapid development of the global candy market, more and more manufacturers are beginning to focus on improving production efficiency and product quality. To meet the growing market demand for hard candy and other candy products, advanced production equipment has become one of the keys to business success. In this article, we will introduce two important equipment: a candy batch roller and a hard candy press cutter, as well as how to find a suitable hard candy press cutter for sale, to help you improve your production capacity and market competitiveness.

Candy Batch Roller – Key Equipment for Hard Candy Production

The candy batch roller is an important part of the hard candy production process. It is mainly used to roll the syrup evenly in the cooled candy batches to help form the initial shape of the candy. It ensures that the syrup reaches the best texture during the molding process by precisely controlling the temperature and humidity, thereby providing stable raw materials for subsequent production steps.

Advantages of Candy Batch Roller

- Precise Control: Allows manufacturers to precisely adjust syrup viscosity, ensuring consistent taste and appearance of the hard candy.

- Improve Efficiency: Automation and precision design significantly boost production efficiency, reducing cycle times.

- Adapt to Diverse Needs: The candy batch roller delivers ideal results in the initial processing stage for traditional hard candy or innovative new products.

Hard Candy Press Cutter – Precise Cutting

In the production process of hard candy, cutting is a crucial step. Hard Candy Press Cutter can quickly and accurately cut batches of syrup into the required shape and size, ensuring the uniformity and high quality of each candy. Compared with traditional manual cutting, the hard candy press cutter provides higher precision and stronger production efficiency.

Hard Candy Press Cutter for Sale – Find the Right Equipment

Demand for hard candy press cutters is rising globally. Manufacturers consider factors like performance, price, and after-sales service when purchasing. There are many models to choose from, suitable for different production needs.

How to Choose the Right Hard Candy Press Cutter?

Related Equipment: Further Optimize the Production Line

In addition to the candy batch roller and hard candy press cutter, the hard candy production line also involves a series of other equipment to help companies improve overall production efficiency.

- Hard Candy Making Machine: Integrate syrup boiling, cooling, forming, cutting, and packaging, automate production, improve efficiency, and ensure consistency and quality.

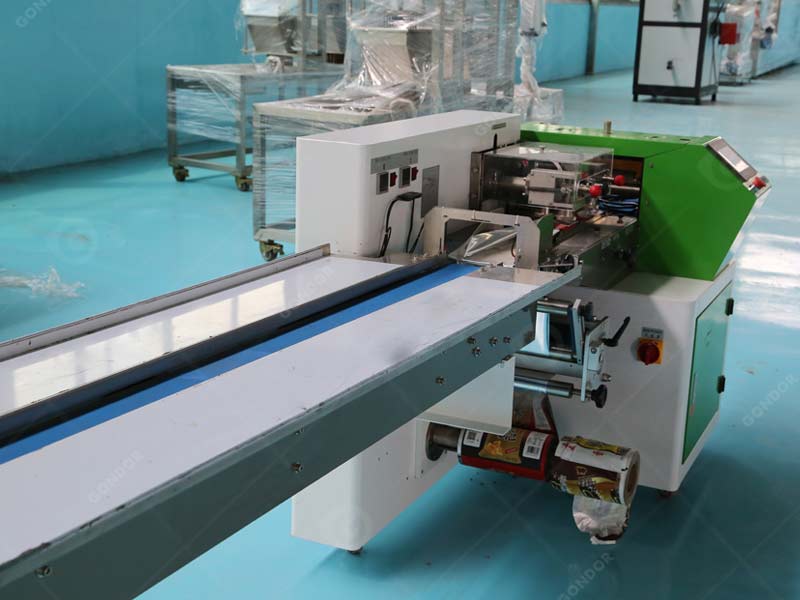

- Automatic Pillow Packing Machine: Automatically package finished candies to ensure safety and hygiene, and support a variety of packaging forms.

- Candy Panning Machine: Coat the surface of hard candy to improve appearance and flavor, increase gloss and protection, and is equipped with a precise temperature control system.

Gondor Hard Candy Making Machine

Gondor Pillow Packing Machine

Gondor Coating Machine

The Future of the Global Hard Candy Production Industry

With advancing technology and changing market demands, hard candy production equipment is continually optimized. Choosing the right equipment helps businesses improve efficiency, reduce costs, and ensure product quality to meet global demand. If you’re seeking reliable, efficient hard candy production equipment, contact Gondor for customized solutions that boost productivity and market share.