As global demand for chocolate grows, chocolate processing equipment is constantly upgraded to improve efficiency and precision. Manufacturers are concerned about optimizing production processes and improving product quality. This article will introduce three key equipment: a chocolate refiner melanger, a machine for melting chocolate, and a chocolate bean packing machine, and explore their roles and industry trends.

Chocolate Refiner Melanger: The Key to Improving the Delicate Taste of Chocolate

In chocolate production, grinding and refining determine the taste. The chocolate refiner melanger can grind raw materials such as cocoa liquor, sugar, etc. into fine chocolate paste.

Working Principle

The equipment uses granite rollers to grind at low speed to make the chocolate smoother and reduce the particle size. Compared with traditional manual grinding, modern equipment can be completed within 48 hours, greatly improving efficiency.

Main Advantages

Machine for Melting Chocolate: Efficiently Melt Chocolate and Improve Production Efficiency

The first step in chocolate processing is to melt solid chocolate for subsequent mixing and processing. A machine for melting chocolate can heat chocolate blocks, chocolate chips, or chocolate beans evenly to an ideal flow state quickly while avoiding overheating or agglomeration.

Equipment Features

Scope of Application

Whether it is a small chocolate workshop or a large-scale production enterprise, a machine for melting chocolate is an indispensable piece of equipment. It is not only suitable for the production of products such as chocolate bars, coated chocolate, and sandwich chocolate but also can be used for food processing such as candy and cakes.

Chocolate Bean Packing Machine: Intelligent Packaging to Enhance Product Competitiveness

In the final stage of chocolate production, packaging affects freshness and market competitiveness. Chocolate bean packing machine can automatically weigh, pack and seal chocolate beans and other granular products.

Main Functions

Industry Trends

As the packaging industry develops towards environmental protection and intelligence, the equipment is constantly upgraded:

Future Trends of Chocolate Production Equipment

In addition to key equipment such as a chocolate refiner melanger, a machine for melting chocolate, and a chocolate bean packing machine, the chocolate processing industry is gradually moving towards automation and intelligence. For example:

- Intelligent Temperature Control System: Ensures the consistency of chocolate taste in different batches.

- Robotic Automated Production Line: Reduces manual intervention and improves production safety and efficiency.

- Data-Driven Optimization: Uses big data to analyze production data and optimize recipes and production processes.

In the future, chocolate processing equipment that integrates AI technology will further enhance production flexibility, help companies reduce costs and improve market competitiveness.

Contact Us to Get Complete Chocolate Processing Equipment Solutions

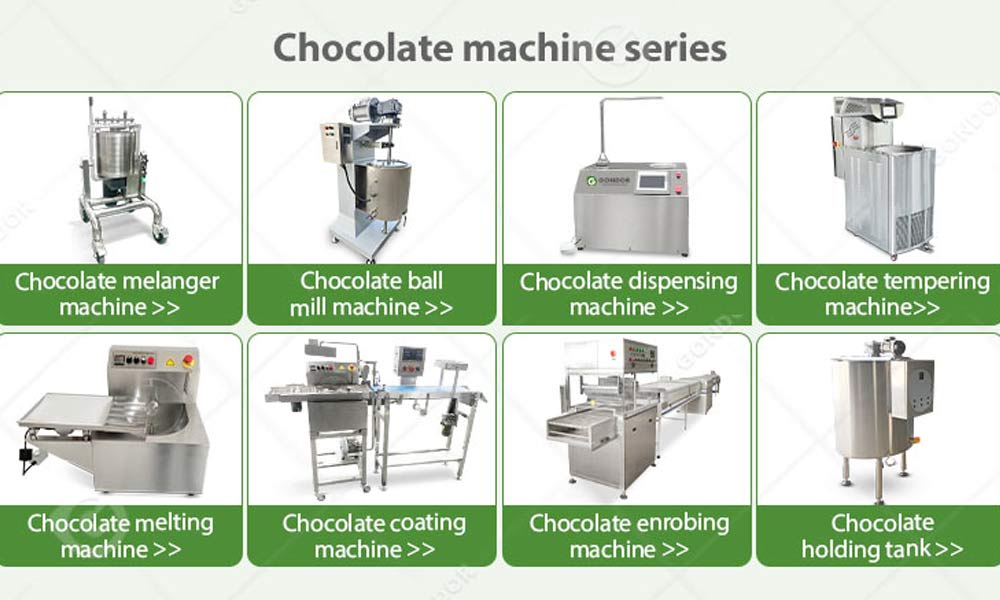

If you are looking for efficient and reliable chocolate processing machine, we also provide other related equipment, such as:

- Chocolate Enrobing Machine: Used to make coated chocolate products, such as chocolate fillings, coated nuts, etc.

- Chocolate Molding Machine: Suitable for automatic molding production of chocolate bars and chocolate blocks.

Please contact us for more equipment details. We will provide you with the best chocolate production solutions to help your business grow!