Gondor Provides Hamburger Patty Forming Solutions for a Vancouver, Canada Client

In early 2026, we received an inquiry from a client in Vancouver, Canada: they had just launched a new meat processing plant, with hamburger patties as its core product, planning to supply local restaurant chains, fast-food chains, and catering companies.

The client had specific capacity requirements: a target output of 1560 patties per hour, and desired high consistency in appearance, weight, and size to ensure a more stable supply chain.

For a newly established plant, the choice of the first production line often determines subsequent production stability, labor costs, product consistency, and order fulfillment capacity. The client wanted a one-time selection that not only met initial production needs but also allowed for future expansion.

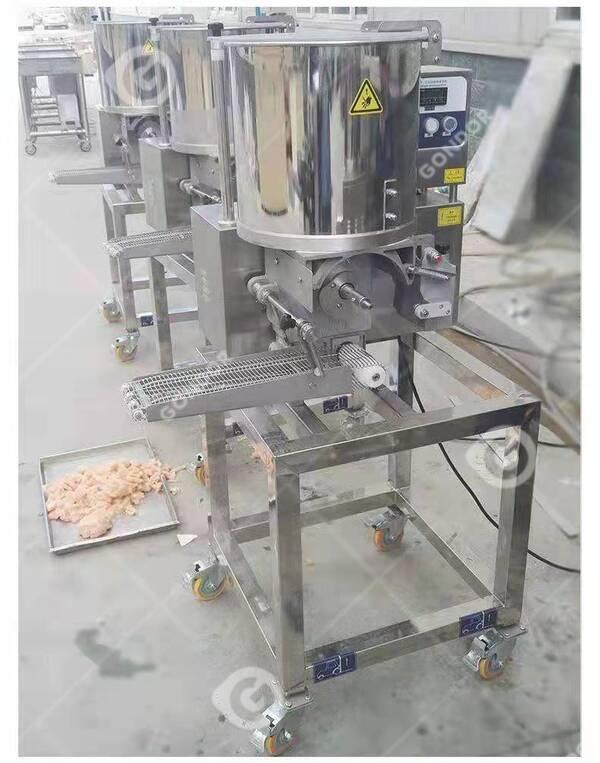

After two months of communication, we successfully assisted the Vancouver-based meat processing startup in building its core hamburger patty production line from scratch. By adopting the Gondor GD-120 automatic meat patty forming machine, the customer successfully solved the problems of high output, customization, and product standardization.

Core Requirements: Stable Production Capacity + Controllable Specifications + Adaptable Packaging Processes

High-quality equipment is only half the battle; understanding the client’s specific business needs is crucial. Gondor Machinery’s technical support team conducted in-depth communication and needs analysis with the Canadian client for two months. During this communication, the client emphasized three essential requirements:

These three points may seem simple, but for meat patty forming machines, they involve several key details such as forming stability, mold matching, output rhythm, hygiene and cleanliness, and adaptability to continuous production.

How Gondor Precisely Meets Customer Needs

Over the past two months, the Gondor team not only answered technical questions about machine performance but also provided advice from a professional food processing perspective:

- We explained in detail how the GD-120 machine can freely adjust the weight of meat patties from lightweight to heavyweight by changing different molds, ensuring that each patty has a consistent thickness, thus guaranteeing uniform cooking results.Precise Control of Weight and Thickness

- Regarding the liner function, which is of concern to customers, we provided a detailed video demonstration showing how the machine automatically places special liner paper under the meat patties during forming. This function perfectly matches the customer’s automation vision.Simulating Real Production Scenarios

- Gondor not only sells machines but also provides layout suggestions for the forming machine, upstream meat grinder, and downstream packaging equipment based on the customer’s factory floor plan, offering the most professional one-stop solution.Layout Consultation

Through this “consultative” sales service, customers are assured that Gondor can provide stable and expected equipment.

From Parameter Confirmation to Solution Implementation

The entire process, from initial communication to final order confirmation, took approximately two months. As the client responsible for the new factory, the initial phase required simultaneous work on factory planning, power supply and production line layout, staffing, and product positioning, leading to more cautious equipment selection.

During this phase, we focused on the following:

Ultimately, after a thorough evaluation of capacity, scalability, and practical production operability, the client selected our Gondor meat patty forming machine, GD-120.

Features of the GD-120 Automatic Meat Patty Forming Machine

- 1. High Efficiency & Stable Capacity

- 2. Precise Customization & Flexibility

- 3. Automated Liner Function

- 4. Food-Grade Hygiene & Durability

- 5. Easy Operation & Low Maintenance

A Professional Food Machinery Supplier

This new Vancouver, Canada plant project has reaffirmed our belief that overseas clients don’t just need “parameter stacking,” but rather production solutions that are implementable, continuously operational, and scalable.

From the target capacity of 1560 patties/hour to the padding function, size customization, and stable grammage, every aspect directly impacts whether our clients can successfully launch production and reliably deliver orders.

If you are also planning to build a new meat processing plant or upgrade your hamburger patty production line, please contact the Gondor team. We can recommend a more suitable patty forming solution based on your target output, patty specifications, back-end packaging methods, plant layout, and power requirements, providing corresponding parameter suggestions and configuration ideas to ensure your production line is on a more efficient and standardized path from the outset.