In today’s highly competitive food processing industry, the demand for small-batch, customized gummy candy production is steadily rising. Moreover, to help small and medium-sized businesses meet the growing need for personalized products, our factory has developed a line of innovative small gummy machines specifically designed for flexible, small-batch candy production. By seamlessly integrating cutting-edge automation, precise temperature control systems, and versatile mold options, Gondor gummy candy making machines not only help our customers achieve efficient production but also ensure consistent quality across every batch. Please check this article for the high performance and reliability of our professional gummy machines. Furthermore, we will examine how our commitment to research and development drives continuous innovation, which results in enhanced equipment performance and improved user experiences.

Core Features of the Small Gummy Machines

The core features of the small gummy machine demonstrate how these gummy candy machines enable small and medium-sized businesses to achieve flexible and precise candy production through highly efficient, automatic systems. In today’s candy manufacturing industry, companies not only need to optimize production efficiency but also ensure product quality, texture, and customization capabilities to meet the diverse demands of the market. With this in mind, we will now take a closer look at the key functionalities of Gondor gummy making equipment, while exploring how its automation and innovative design help clients enhance their competitiveness.

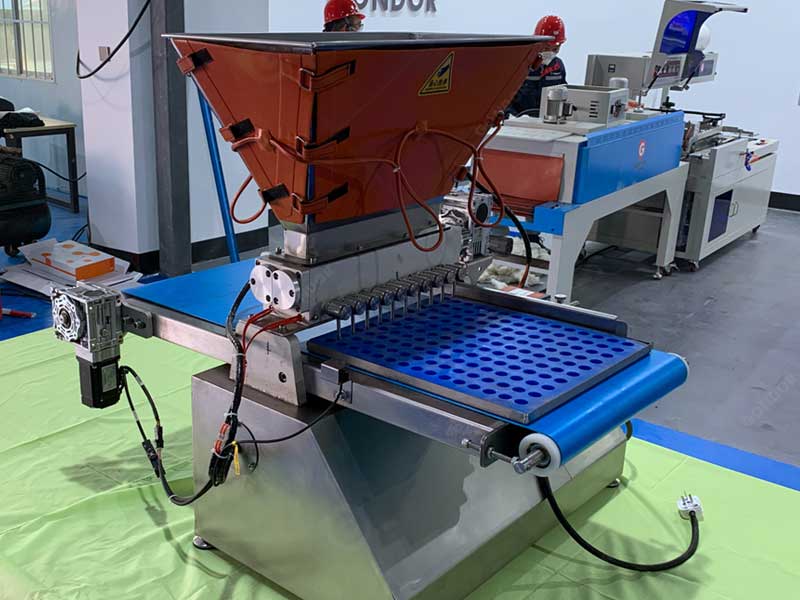

Automated Production System

Our small batch gummy machine is equipped with an advanced automated production system, which not only significantly reduces manual intervention but also greatly increases overall production efficiency. Furthermore, the gummy machine’s intuitive and user-friendly design allows operators to easily control and monitor the entire production process through a simple yet highly effective touchscreen interface. This seamless one-touch operation not only simplifies the production process even further but also makes the machine perfectly suited for small businesses and startups, which enables them to achieve consistent and stable candy production with minimal resources and manpower.

Precise Temperature Control

When it comes to gummy candy production, maintaining precise temperature control is absolutely critical for achieving the perfect texture and flavor. The small batch gummy machine is equipped with an advanced temperature control system, which ensures that the syrup consistently remains at the optimal temperature throughout the entire production process. This level of precision not only helps avoid the risks of overheating or undercooling but also guarantees consistent candy quality. Therefore, this feature is particularly important for gummy candies that require a delicate balance of flavor and texture, where even minor temperature fluctuations could compromise the final product.

Versatile Mold Selection

With the growing market demand for personalized candy products, the small batch gummy making equipment offers exceptional versatility through a wide range of mold options. This extensive selection allows users to easily switch between different shapes and sizes, thus catering to a variety of consumer preferences. Moreover, this flexibility not only enhances production capabilities but also makes it significantly easier to meet custom orders. Whether producing heart-shaped, star-shaped, or other intricate candy designs, our gummy machines deliver both high efficiency and precision. Additionally, we offer custom mold services, which enables clients to create unique candy products that truly stand out in the marketplace.

Efficient Mixing and Pouring System

Our gummy candy making machine also comes equipped with a highly precise mixing and pouring system, which can ensure that syrup, colors, and flavors are evenly distributed throughout the entire production process, thereby guaranteeing consistency in both taste and texture for every single candy piece. What’s more, the advanced pouring system of small gummy machine ensures accurate portioning, which not only minimizes waste but also maximizes production efficiency. Particularly for small-batch gummy production, these features are especially important, as they help control production costs while still maintaining exceptionally high quality standards.

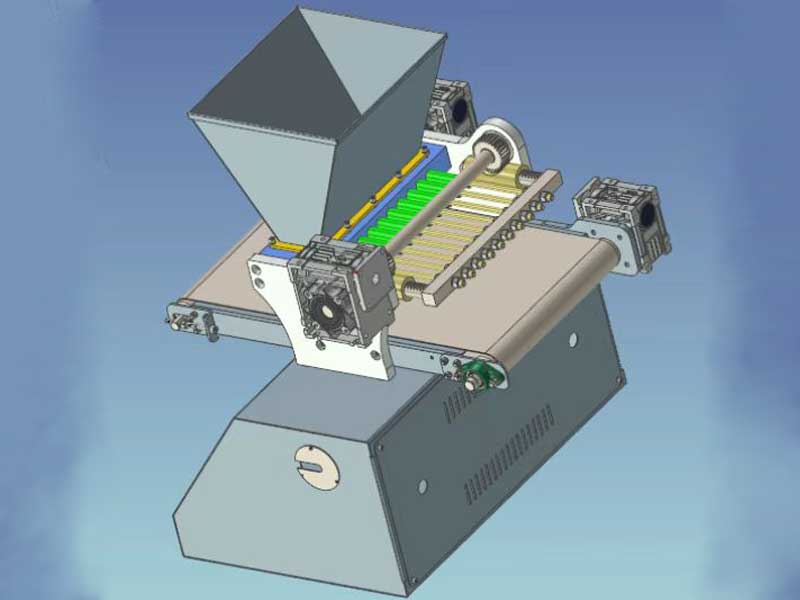

Innovative Design of Gondor Small Batch Gummy Machines

The innovative design of the small batch gummy machine not only demonstrates cutting-edge technology but also reflects a deep understanding of the practical production needs of businesses. At Gondor machinery, we are committed to not only enhancing equipment performance but also providing highly flexible, eco-friendly, and intelligent solutions through thoughtful, innovative design. Therefore, with these features working together seamlessly, we can help businesses significantly improve operational efficiency, reduce overall costs, and promote more sustainable production practices in their day-to-day operations.

Small Gummy Machine: A Flexible and Efficient Gummy Making Equipment

In summary, the small gummy machine from Gondor machinery, a professional supplier and manufacturer, combines exceptional production efficiency with remarkable operational flexibility, which makes it particularly suitable for small-batch custom gummy production and the diverse needs of small to medium-sized businesses. Leveraging our leading expertise in food processing equipment development and innovation, Gondor company provides customers with high-quality, reliable candy production solutions, which can help them maintain a strong competitive edge in the market. For more information about our small batch gummy machine and other advanced food processing and packaging machinery, please feel free to visit our website or contact our dedicated sales team. We look forward to offering you tailored equipment solutions that will help your business thrive and grow.