The chocolate production industry is in the process of continuous innovation and optimization, and more and more advanced equipment is introduced into the production line to improve production efficiency and product quality. This article will discuss the important applications of the chocolate depositor machine and ball mill chocolate in chocolate production and their technological progress.

Key Functions and Advantages of Chocolate Depositor Machine

The chocolate depositor machine is the core equipment in modern chocolate production. It is mainly used to accurately pour liquid chocolate into the mold to ensure the accuracy and consistency of chocolate molding. Compared with traditional manual pouring, chocolate depositor improves production efficiency and product quality, especially for large-scale production. The following are its main advantages:

Diversified Functions of Chocolate Depositor Equipment

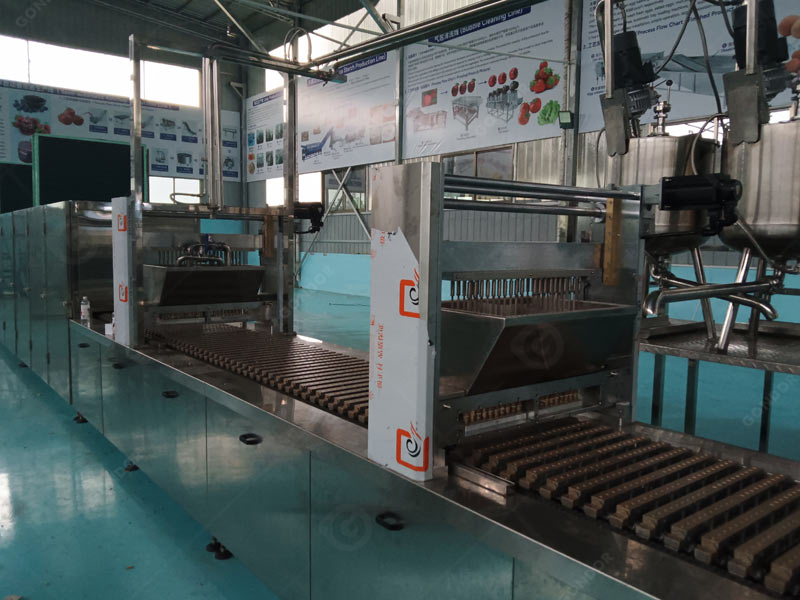

Chocolate depositing equipment is indispensable equipment in chocolate production and is widely used in the production of chocolate candies, slices, bars, and other products. As consumers’ demand for chocolate shapes and flavors increases, chocolate depositing equipment has gradually developed more flexible functions.

Nowadays, chocolate depositing equipment can produce chocolates in various shapes, such as spherical, heart-shaped, flower-shaped, etc., to meet personalized needs. At the same time, it can also cooperate with equipment such as coolers and demoulding machines to improve production efficiency and optimize the overall production line.

Ball Mill Chocolate: Ensures a Uniform and Delicate Chocolate Taste

In the process of making chocolate, the fineness of the chocolate raw materials directly affects the taste and quality of the chocolate. Ball mill chocolate, as a common chocolate grinding equipment, has excellent grinding performance and can grind the cocoa solids and sugar particles in the chocolate to the micron level, ensuring the smooth and delicate taste of the chocolate.

The chocolate ball mill machine adopts the ball milling principle, using the interaction between the grinding medium (such as steel balls) and the raw materials to continuously grind the particles until the required fineness is reached. Compared with traditional grinding equipment, ball mill chocolate can effectively reduce energy consumption and improve the overall efficiency of the production line while improving product quality.

Future Trend: Integration of Intelligent and Automated Equipment

With the continuous advancement of technology, chocolate production equipment is moving towards a more intelligent and automated direction. This trend can not only reduce labor costs but also improve production accuracy and efficiency. The intelligent integration of equipment such as chocolate depositing machines and ball mill chocolate makes the entire production process more efficient and precise. The following are several key features of this development trend:

These technological innovations will further promote the transformation of chocolate production to intelligence and automation, not only improving production efficiency but also maintaining high-quality product output.

Extension: All-Round Equipment for Chocolate Production Line

In addition to chocolate depositor machines and ball mill chocolate, modern chocolate production lines also include chocolate tempering machines, chocolate coolers, chocolate packaging machines,s and other equipment, which work together to ensure that chocolate is accurate and efficient in every link from raw materials to finished products.

We provide one-stop chocolate production line solutions to meet different scale and product needs, helping you improve production efficiency and product quality. With the continuous upgrading of industry technology, intelligent, environmentally friendly, and efficient equipment will be the key to improving production efficiency and competitiveness. Welcome to contact us for more details.