With the increasing global demand for chocolate, the chocolate manufacturing equipment market faces new opportunities. The demand for efficient and precise equipment is constantly increasing from small and medium-sized enterprises to large factories. This article will analyze industry trends and equipment selection recommendations for devices such as candy coaters.

Chocolate Manufacturing Equipment Market Status

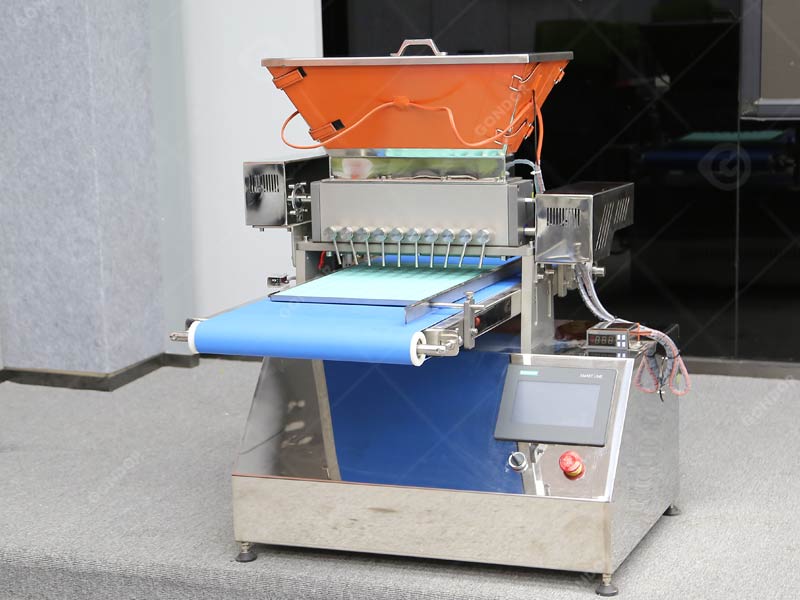

The current market demand for chocolate equipment is strong. From improving production efficiency to meeting customized needs, equipment selection is becoming increasingly diverse, including raw material processing, mixing, injection molding, coating, and packaging. In recent years, small, modular, and highly automated equipment has been favored. For example, the tabletop chocolate depositor is popular among small and medium-sized enterprises and family workshops because of its flexibility and convenience, while the candy coater helps manufacturers expand product categories and increase added value.

Table Top Chocolate Depositor – Ideal for Small Businesses

Features and Benefits

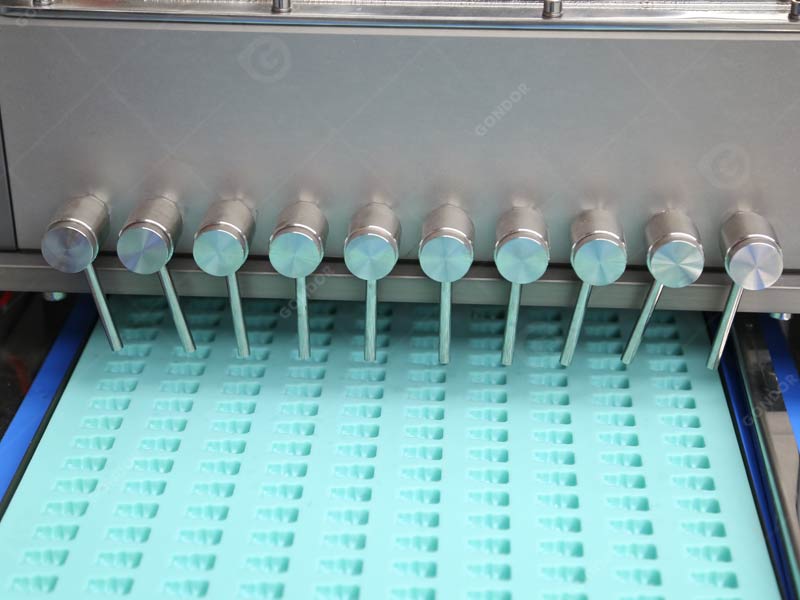

The table top chocolate depositor is the preferred equipment for small businesses and artisan chocolate brands. This equipment is compact and occupies little space, making it ideal for small-batch production and new product development. Its main features include:

Application Scenarios

Many handmade chocolate workshops and small and medium-sized enterprises are using this equipment to quickly respond to market demand, such as seasonal gifts, customized chocolates, etc. The high cost-effectiveness of desktop equipment makes it an entry-level choice, especially suitable for users with limited budgets but pursuing professional quality.

Candy Coater – Adding Flavor and Appearance to Chocolate Products

Innovation Trends

Candy coater is one of the indispensable equipment in chocolate production, especially in the production of coated products (such as chocolate nuts and sugar-coated nuts). Modern candy-coating machines have the following characteristics:

Market Trends

Consumers are increasingly demanding chocolate products with a unique appearance and rich taste, prompting more and more companies to invest in upgrading coating equipment. The flexibility of candy coater not only improves product quality but also helps companies reduce scrap rates and save production costs.

How to Choose Suitable Chocolate Making Equipment for Sale?

As the demand for chocolate grows, production equipment is becoming increasingly diversified, including chocolate melting equipment, grinders, conching machines, etc., to meet the different needs of small workshops to large factories. When choosing suitable equipment, industry experts recommend that manufacturers focus on the following factors:

Seize Opportunities – Choose the Right Chocolate Equipment

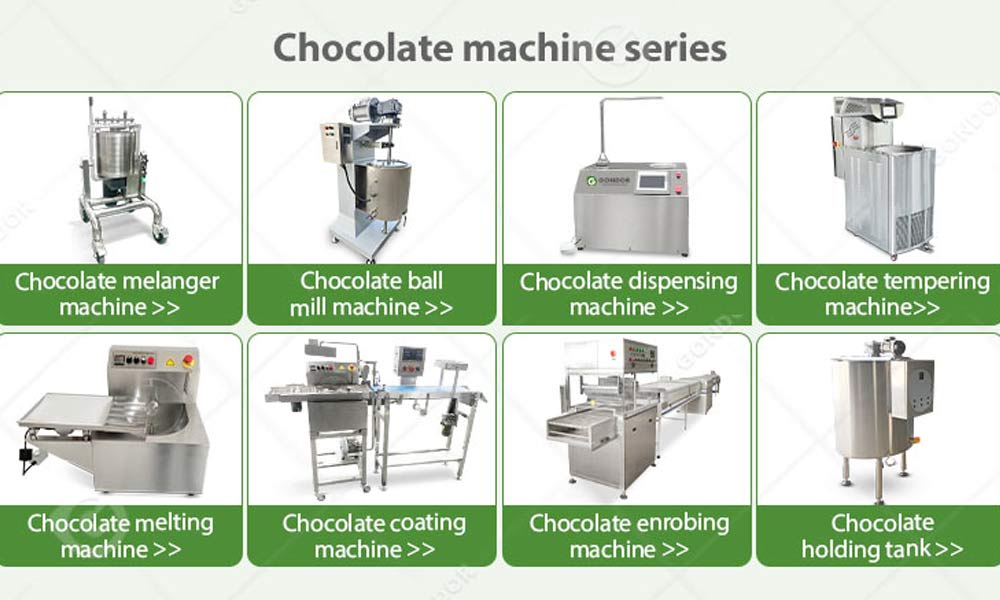

In addition to the tabletop chocolate depositor and candy coater, there are many other key equipments in chocolate production, such as:

- Chocolate Grinder Machine: Used to process cocoa raw materials to ensure the fine texture and high-quality taste of chocolate.

- Chocolate Tempering Machine: Accurately control the temperature of chocolate, improve gloss and taste, and prevent crystallization problems.

In the current global market, the demand for chocolate manufacturing equipment is growing rapidly, and each equipment has its unique advantages and market positioning. Whether you are a small business or a large manufacturer, choosing the right equipment is the key to ensure success. For more information about chocolate production equipment, please browse our website or contact the Gondor professional team directly!