As the candy manufacturing industry continues to grow rapidly, the demand for efficient and automatic candy making equipment is also increasing. Therefore, choosing the right candy manufacturing equipment is crucial not only for improving production efficiency but also for ensuring product consistency and enhancing market competitiveness. Whether you are a small business, startup, or large manufacturer, selecting the proper machinery can have a significant impact on your success. Here, investors in confectionery industry can learn a lot from the comprehensive comparison of different candy molding machines – gummy depositing machine, which can help you make an informed decision based on your specific production needs.

Vertical Gummy Candy Depositor Machine

Tabletop Gummy Candy Depositor Machine

Introduction to Gondor Gummy Depositing Machine

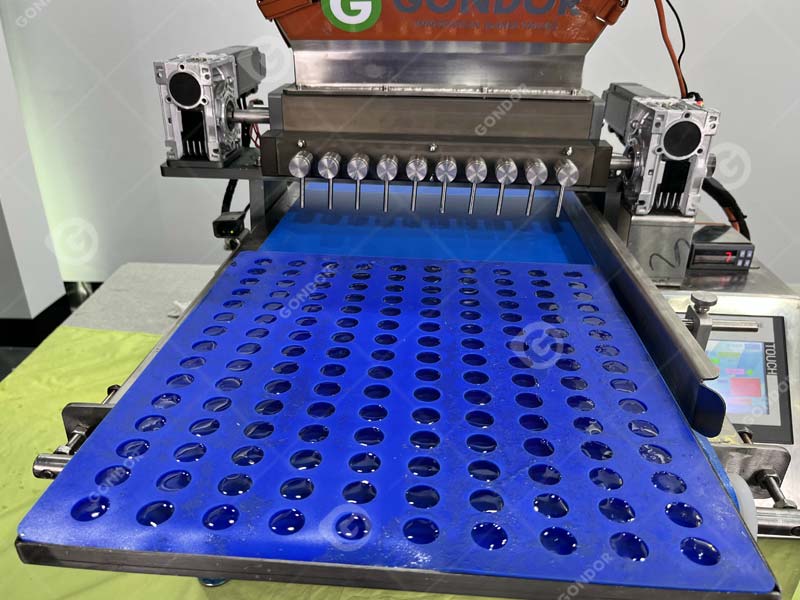

Molding Process of Efficient Gummy Depositing Machine

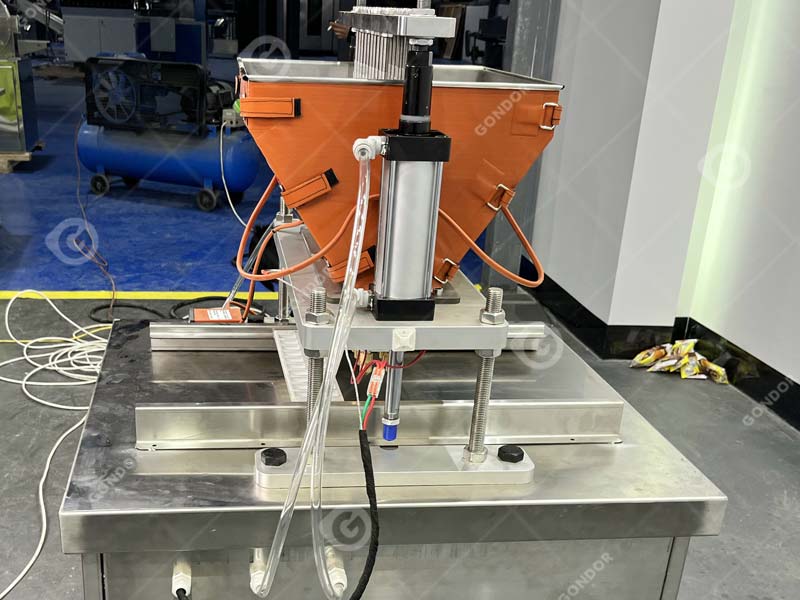

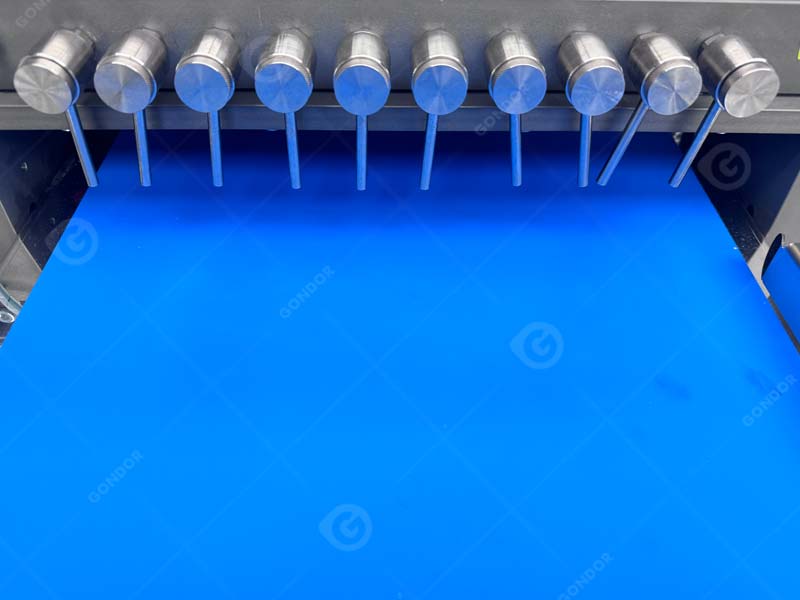

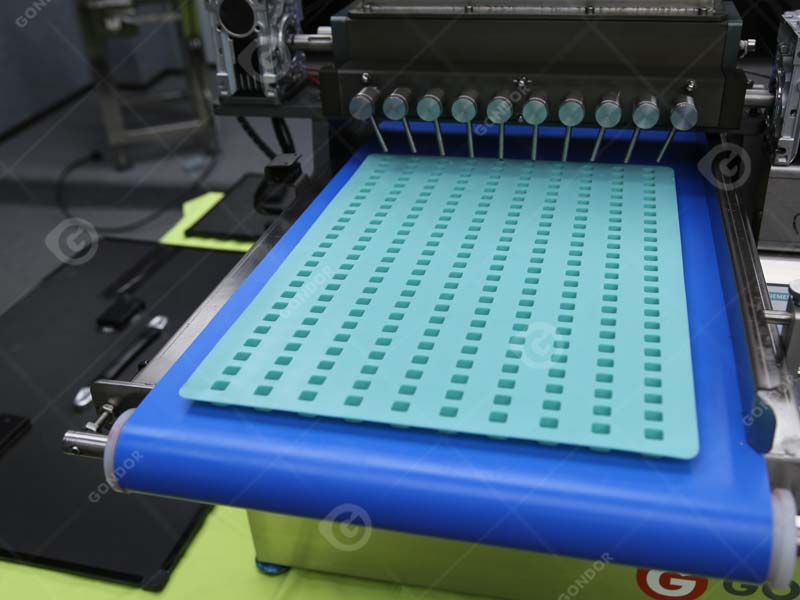

At Gondor Machinery, our gummy depositing machine leverages state-of-the-art injection molding technology, which can ensure the precision in every step. This advanced process carefully and accurately injects liquid candy into molds, which guarantees a consistent shape, size, and weight for each piece of candy. As a result, this candy making equipment is perfectly suited for producing high-quality, uniform products, such as gummy candies and jellies. What truly sets this machine apart is its exceptional accuracy, which makes it the ideal choice for companies that demand precision and reliability in every batch they produce.

Gummy Depositor Machine: Speed and Capacity

What’s more, the gummy depositing machine stands out for its exceptional production capacity. And it is specifically designed to handle large-scale automated production lines with ease, which makes it an ideal solution for businesses seeking high efficiency. Not only can this candy making machine process a substantial volume of candy products in each cycle, but it also significantly reduces manual labor, thereby boosting overall production speed. Moreover, its advanced design ensures that while optimizing production time, there is no compromise on product quality. Therefore, our gummy depositor machine can be suitable for medium to large factories with demanding production schedules and the need for consistent, high-quality output.

Additional Advantages of Gummy Depositing Machines

- Exceptional Flexibility:

One of the standout advantages of our gummy depositing machine is its remarkable versatility. Thanks to its advanced engineering, this machine is capable of producing candies in a wide variety of shapes, colors, and flavors, which enables candy manufacturers to easily adapt to changing consumer demands. Moreover, it can even incorporate functional ingredients such as vitamins or supplements, which allows businesses to create innovative, health-focused products. This flexibility makes the equipment ideal for both traditional candy production and the development of specialized, value-added products, which gives manufacturers a competitive edge in the market. - Easy Maintenance

In addition to its impressive production capabilities, the gummy depositing machine is designed with easy maintenance in mind. Its streamlined structure allows for quick and efficient cleaning, which significantly reduces downtime and ensures continuous, uninterrupted production. This design advantage of candy pouring machine is particularly beneficial for candy manufacturers who aim to maximize productivity and minimize operational disruptions. As a result, this candy making equipment is an excellent choice for most companies that prioritize efficiency and reliability in their production processes of gummy candies. - Sustainability and Efficiency

Furthermore, the gummy depositing machine stands out for its eco-friendly and energy-efficient design. When compared to traditional candy making equipment, this machine optimizes material use while significantly reducing energy consumption. By doing so, it not only lowers operational costs but also minimizes waste, which supports manufacturers in achieving their sustainability goals. This environmentally conscious design contributes to more sustainable production practices, which aligns with the growing demand for eco-friendly manufacturing solutions. Ultimately, it benefits both the environment and the bottom line, which makes it an attractive option for forward-thinking manufacturers.

Comparison with Other Candy Molding Machine

In contrast to traditional candy molding equipment, such as candy pressing or extrusion machines, the gummy depositing machine offers significant advantages in automation and production efficiency. Its ability to reduce manual intervention while enhancing production speed makes it an ideal choice for mid-to-large-scale production. Traditional methods may still serve specific applications, but they fall short when compared to the automation and precision provided by the gummy pouring machine.

Small Gummy Depositor: A Flexible Solution for Small-Scale Production

Small Gummy Depositor: Features and Benefits

The small gummy depositor is specifically designed to cater to small-scale production needs. Thanks to its compact size and user-friendly operation, it becomes an excellent choice for small factories, workshops, or laboratories that require efficient candy production on a smaller scale. Despite its smaller size, the small gummy depositor does not compromise on performance; it still delivers remarkable precision and consistency in candy molding. This allows small-scale candy producers to maintain high production standards while achieving both efficiency and quality in their manufacturing processes. In this way, it offers the perfect balance of cost-effectiveness and reliable performance, which makes it a valuable asset for businesses with smaller production demands.

Application Scenarios of Small Gummy Depositor Machine

- Ideal for Small Factories and Craft Workshops

The small gummy depositor is perfectly tailored for small businesses or startups that are looking to enter the candy manufacturing market. With its lower initial investment cost and enhanced flexibility, it allows businesses to quickly adapt to evolving market trends. Moreover, this machine provides the versatility needed to easily produce customized products, which makes it a highly efficient and practical option for smaller operations that need to balance costs and agility. - Excellent for Product Development and Experimentation

Additionally, the small gummy depositor is an ideal choice for companies focused on new product development or conducting market trials. Thanks to its affordability and adaptability, this machine provides an accessible and cost-effective solution for small-batch production runs. Furthermore, it allows manufacturers to quickly respond to customer feedback or adjust to changing demands, giving businesses the flexibility to test new ideas and innovations without significant financial risks.

Cost-Effectiveness of Our Small Gummy Depositor Machine

Compared to larger machines like the candy depositing machine, the small gummy depositor offers the distinct advantage of requiring a significantly lower initial investment. Moreover, it incurs substantially lower operational and maintenance costs, which makes it an ideal choice for businesses looking to minimize expenses without sacrificing quality. As a result, this machine is a highly cost-effective solution, especially for startups or companies operating on a limited budget. Despite its smaller size and lower cost, the small gummy depositor still allows manufacturers to produce customized, high-quality gummy products, ensuring they can meet market demands while maintaining operational efficiency.

Comparison with Gummy Depositing Machine

- Production Scale: While the gummy depositing machine is ideal for large-scale production, the small gummy depositor is better suited for low-volume, customized production lines. This makes it an excellent choice for businesses that prioritize personalization or niche markets.

- Enhanced Flexibility: In addition to its cost-effectiveness, the small gummy depositor offers greater flexibility and ease of use compared to the gummy depositing machine, which makes it an ideal solution for new businesses or those exploring new market opportunities.

How to Choose the Right Equipment Based on Your Production Needs

Selecting the right candy production equipment is critical for optimizing your operations and achieving business success. Whether your focus is on large-scale production or smaller, customized batches, the choice of equipment can significantly impact your efficiency, cost management, and ability to meet market demands. Below, we provide a comprehensive guide to help you evaluate the best equipment based on your production scale, budget, and product requirements.

- Large-Scale Production: If your business is focused on high-volume and fully automatic production, the gummy depositing machine would be the most suitable choices. These machines are designed to handle large operations efficiently, and can offers the necessary speed and capacity to meet significant production demands. They are ideal for manufacturers aiming for mass production with minimal manual intervention.

- Small-Scale and Custom Production: For smaller factories or startups that specialize in small-batch or custom production, the small gummy depositor provides a more flexible and cost-effective solution. Due to its adaptable design, it’s perfect for businesses looking to produce personalized or niche products, which offers the flexibility needed to accommodate lower production volumes and frequent changes in product lines.

- Initial Investment: The small gummy depositor offers a lower initial investment and reduced maintenance expenses, which makes it a practical choice for businesses operating on limited budgets. Its affordability allows smaller companies to enter the market without compromising on production quality or versatility.

- Long-Term Benefits: Conversely, for companies with long-term growth strategies and high production goals, investing in either the gummy depositing machine can deliver significant returns over time. These machines are built for efficiency and high capacity, and it means they can support large-scale operations, reduce manual labor, and ultimately enhance profitability as production scales up.

- Diverse Product Range: If your business needs to produce a wide range of candies with varied shapes, flavors, and formulations, the gummy depositing machine is the best fit. Its versatility allows it to meet diverse production needs, which enables you to stay competitive by offering a variety of products.

- Custom Products: However, if your focus is on producing custom, small-batch, or niche products, the small gummy depositor is the most suitable option. Its flexibility in production allows you to create unique and personalized items, which can meet the demands of a specialized market while keeping costs manageable.

Reach Out Gondor to Help Customers Make an Informed Choice

No matter if you are a startup, a small workshop, or a well-established manufacturer, Gondor Machinery has the right candy production equipment to meet your needs. We invite you to contact us for more information or to schedule a free food processing equipment consultation. At Gondor machinery, we are committed to providing our customers with the best possible guidance. Whether you’re looking for a cost-effective solution for small-batch production or need high-capacity equipment for large-scale operations, our team of experts is here to assist you every step of the way. We take the time to understand your unique requirements and offer tailored recommendations to help you make the most informed decision.

Let Gondor Machinery be your trusted partner in selecting the right equipment that will not only enhance your production capabilities but also position your business for long-term success in the competitive candy manufacturing industry.